Construction Method Of Concrete Slab On Grade

Slab on grade belongs to concrete floor slabs which are poured at grade or ground level to develop a foundation for a home. Prior to start the construction, contractors excavate the soil adjacent to the area where the foundation should be constructed and ensure that the ground has sufficient strength to support the structure.

Normally, the periphery of the slab is very dense as compared to the rest of the surface. This section has similarity with footer that facilitates to circulate the weight of the exterior walls uniformly over the soil underneath the structure. Slab on grade foundations are suitable for the areas where the soil is unusable for crawl spaces or basements.

Grade slabs are provided in areas where the ground is not solidified. This type of slabs may or may not include reinforcement in it. The inclusion of reinforcement depends on the floor loads and local building codes.

The thickness of Grade Slab should be at least 4 inches. If porosity exists in soil, the thickness of the slab should be raised. To maintain safety, a layer of gravel & bitumen should be placed on earth prior to arrange concrete slab to stop the penetration of moisture content into the slab.

Slab on Grade is categorized as follow:

1. Supported Slab on Grade

2. Monolithic Slab on Grade

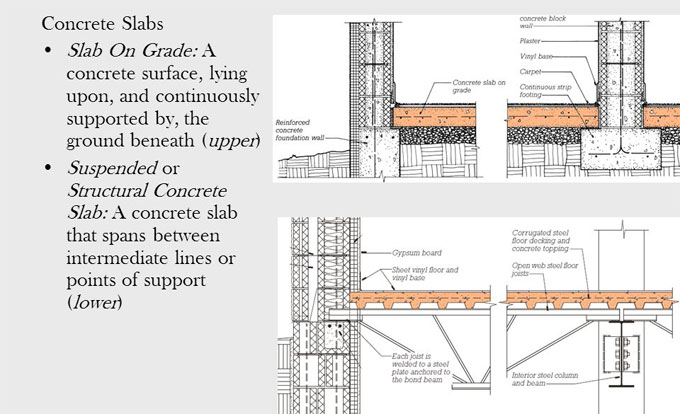

Supported Slab on Grade / Grade Slab: Supported grade slab or slab on grade foundation should be used when the conventional footings are already set up on site to uplift the columns. Under this system, the wall is laid on a footing and the grade slab stands on a layer of gravel and moisture barrier.

The formwork applied for plinth beams operates as batter boards for slab mould. There is an expansion joint among concrete slab and wall to reduce the stress throughout high-temperature days. Control joints are set in a planned grid with chalk lines to manage occasional cracking on the slab.

Monolithic Slab on grade: There are no footings for monolithic grade slab, the concrete slab itself functions as a footing for the building; and the columns, walls are uplifted from the grade slab. This type of slab is structured with batter boards around the slab based on the plan and the concrete is poured inside batter boards. These batter boards operate as a mould to detect the slab corners.

Grade slabs normally stand on the layers of gravel and moisture barrier. These layers can resist penetration of water into the slab to develop surface cracks.

The periphery of the grade slab is very dense as compared to the rest of surface. This dense section operates as a mini footing and facilitates to circulate top loads more consistently over the adjacent soil.

Construction Method: Prior to cast slab on grade, the excavation of earth is done to the desired depth along with compaction to drive out air voids. Batters are leveled and provided in exact location based on the plan prior to concrete pour. These boards function as a concrete mould to facilitate detecting the slab corners.

After that, soil investigation is performed to design the thickness of the slab. After obtaining the results, the layers of gravel and moisture barriers (bitumen) is again poured on the ground. These layers are used as a sub-base for slab and resist the infiltration of moisture into the slab.

The thick concrete is poured at the edges to form an solid footing and reinforcement rods are placed to increase the strength of the edges.

To reduce random cracking on the surface, the concrete should be cured and dried for long times.

The expansion joint should be arranged among the wall and slab. The control joints on the slab are leveled with chalk lines prior to pouring which can check random cracking.