Why use BIM for Reinforced Concrete Modeling?

Building Information Modelling (BIM) helps to address the challenges of the concrete detailing process, including the installation challenges and assembly clashes. The increased visualisation feature, collaborative nature and the parametric detailing feature of the BIM software help to drive a high level of efficiency in the precast concrete construction process.

The BIM-based concrete detailing process also helps to streamline the overall construction procedure for the precasters, structural engineers, and prefabrication companies. BIM tools help to create precast concrete designs, shop drawings, fabrication, cost estimates and scheduling estimates, which influence the cost-effectiveness and enhance the constructability. The exact visualisation feature of the BIM tool helps to improve the precast concrete detailing process.

Process of implementing BIM for reinforced concrete

BIM software has been implemented to achieve the ideal workflow for reinforced concrete. The implementation procedure follows several steps, which are as follows:

Testing

The company's requirements have been assessed by the testing procedure. This process also helps to evaluate irregularities. Thus, professionals can develop ideal BIM solutions that help speed up the process of concrete detailing and concrete reinforcement.

Advancing

The templates have been created for each type of reinforced concrete document, which is an important stage. The right template and filter help to make the development process of the reinforced concrete document for the building structure easier.

Training

Training is a crucial stage for the 3D reinforced concrete modelling. In this regard, the BIM software is effective. In this phase, suitable training has been given to the lead engineers, structural engineers, draftsmen and management team members, which makes each member of the organisation aware of the advantages of the 3D BIM models of the reinforced concrete.

Executing

This phase enables the BIM expert to join the task force and work efficiently. This helps to demonstrate the value of the BIM software, as well as helps to foster cross-departmental collaboration. The most reliable documentation procedure has been enabled by the BIM software, which influences a more accurate concrete detailing process.

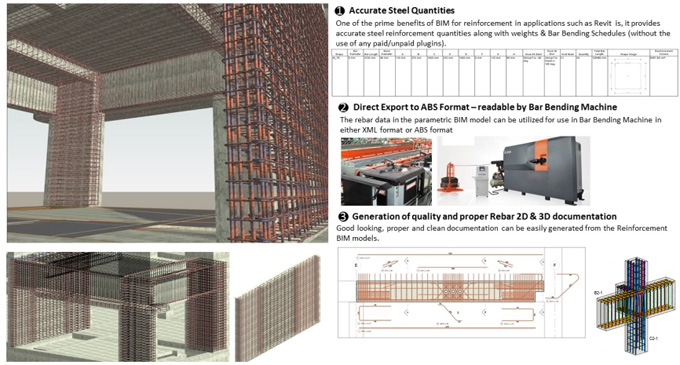

Advantages of BIM-based concrete detailing for the construction project

There are numerous advantages of using BIM solutions for the concrete detailing process for several construction projects. These advantages are as follows:

Clash-detection and informed decision-making feature

BIM tools help to get a structural 3D model, which helps combine the architectural and MEP design models. This also helps to influence the identification of the project clash, which helps to generate real-time feedback for the resolution of the clashes by the prefabrication team members with the help of the 3D model coordination.

This 3D model also influences the higher accuracy in the forecast concrete detailing process. Thus, these 3D models reduce the need for rework by mitigating project delays as well as help to promote the seamless integration of the precast elements on the construction site.

Better onsite coordination and quality fabrication

The coordinated 3D models help to carry the list of the precast elements along with the section and views. The higher construction visibility has been achieved by comparing the erection drawings, data-accurate shop drawings, and 3D models, which helps to improve the onsite coordination.

The bill of materials has been extracted from the 3D models precisely, which helps to reduce the material waste and overall costs of the project.

Inserting and analysing the concrete detailing process

The 3D precast detailing process helps to speed up the entire pre-casting procedure. This also helps to streamline the 3D design process along with the real-time updates. The automation tools, including plugins, or Dynamo, help to promote the concrete detailing, 3D modelling and shop drawing process, thus improving the precast detailing and prefabrication procedure.

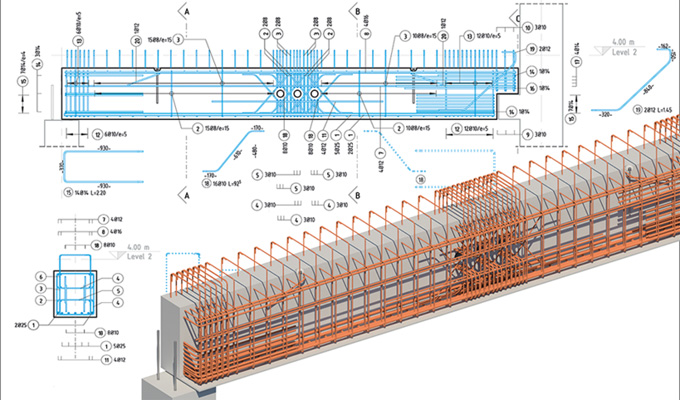

Better concrete detailing process

The 3D BIM models improve the detailing of precast elements, such as auto-format dimensions and placing rebars, and this can be done by streamlining the 3D design process. The customization of the precast product has also been improved with the help of the accurate 3D models. The accurate precast concrete elements also help to ensure the achievement of a better design finish, as well as reducing the risks of material wastage.

Higher visualisation of the BIM models

A 360-degree view of the precast elements has also been achieved by the 3D BIM models, which helps to add the appropriate fabrication pre-casting details and annotations. This also helps to reduce the risks of the projects and minimizes the need for rework.

Improved collaboration

The coordination among various disciplines, including structure, architecture and MEP industry, can be improved by adding scheduling details into the precast concrete models. This helps to allow the manufacturer to improve and plan their material purchasing procedure, the duration of the manufacturing process and also improve their delivery schedule.

To learn more, watch the following video tutorial.

Video Source: Autodesk Building Solutions

The use of cloud-based platforms, such as BIM360, also helps to improve the sharing of the 3D models and other documentation in real-time, thus improving the collaboration among the project team members and improving the reinforced concrete detailing process.