Design Guide for Composite Box Girder Bridges

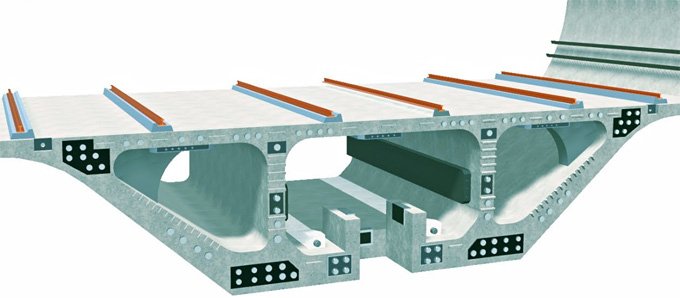

The design of the box girder bridge helps to reduce the self-weight of the entire bridge structure. The box girder bridges have been widely used in highway bridges and railway bridges. The steel box girders and concrete composite box girders can be used for the longer span bridges, in which the self-weight of the bridges has been minimised.

The box girder bridges help to provide an excellent appearance to the bridge structure, as well as increasing the durability of the bridge structure. In addition, there are no traps for the moisture and dirt within the box girder bridges.

Different applications of box girder bridges

The box girder has different applications because of its different structural forms.

Highway bridges

In the highway bridges, different types of box girders have been used, which are as follows:

Composite box girders

The composite box girders have been used in those highway bridges, which span between 45m and 100m. In this case, narrower rectangular steel box sections have been chosen for the highways.

Steel box girders

The steel box girders have been applied in those highway bridges, which span more than 200m. Stiffened steel top flange has been carried out on the roads of those highway bridges, which are lighter in weight and also complex to fabricate.

Importance of choosing steel box girders in construction

➢ Using steel box girders helps to reduce the requirement for support points in the bridges.

➢ The steel box girder also helps to enhance the durability of the bridge structure, as well as reducing the maintenance of protective coatings on the bridges.

➢ The use of steel box girders in the bridges also helps to provide an excellent visual appearance to the bridge structure.

Cable-supported box girders

In the case of the very long span highways, the cable-supported box girders have been used along with the steel box girders or composite box girders.

Railway bridges

The standard box girders have been employed in the railway bridges, which cover about 21m to 39m spans of the bridges. In this case, the box girders of the railway bridges have been stabilised by the linear rocker bearings.

Footbridges

Box girders are also used in the footbridges, whose span is about 30m. In this case, all steel configurations have been adopted within the footbridges.

Concept about the prestressed concrete bridge

Prestressed concrete has been used in the bridge structure, which is a variety of modern concrete. The prestressed concrete helps to strengthen the span length of the bridge structure, along with less weight, as the stress or tension has been applied to the concrete before placing it into position. The prestressed concrete beams have the ability to span longer distances as compared to the reinforced concrete beams.

In addition, the prestressed concrete beams are also lighter in weight and require less concrete without any kind of cracks within the beams, thus making the bridge structure more durable for a longer period of time. The first prestressed concrete bridge was constructed in 1950 in the United States, named the “Walnut Lane Bridge”.

Discuss the different types of prestressed concrete bridges

The prestressed concrete that has been used in the bridge construction can be made by following different procedures, which are as follows:

Post-tensioning concrete bridges

In this type of concrete, the cables are required to tie the row of concrete blocks together. These types of concrete have been known as “post-tensioning” as the concrete blocks have been tensioned with the help of a conventional concrete block-casting process after production.

In this case, a hydraulic jacking device is required for tightening the cables and creating the required tensions for the bridges. Only simple equipment is required during the construction of the post-tensioning concrete. In addition, the post-tensioning is limited to the smaller beams and slabs. In the Minnesota bridges, the post-tension concrete has been used.

Pretensioning concrete bridges

This is another type of prestressed concrete which also used in several bridge structures. In this case, the concrete has been poured around the tensioned cables. After hardening the concrete, the cables have been held in place. After the concrete becomes solid and cures properly, the end of the tensioned cable is cut and released into the slabs or beams.

The process of creating the pretensioning concrete is more complicated as compared to the post-tensioning concrete. During the construction of the pretensioned concrete, large casting beds are necessary to hold the steel cables in a highly tensioned state.

To learn more, watch the following video tutorial.

Video Source: BridgeHAWK®

Because of the transportation restrictions between the plant and the bridge construction site, and also because of the limited availability of cranes to lift the beams into the bridge construction site, the length of the pretensioning concrete beams has been restricted.