Unraveling the Significance of Workability: A Comprehensive Guide to Concrete Flow Table Testing in Construction

In the intricate world of construction, where precision and performance are paramount, the workability of concrete stands as a pivotal factor. The ability of concrete to be effortlessly mixed, placed, and compacted is a key determinant of project success.

Understanding Concrete Workability - Definition and Importance:

Workability in concrete refers to its ease of handling, placing, and compacting during construction. It is a multidimensional property influenced by factors such as water content, cementitious materials, aggregates, and admixtures.

The workability of concrete is vital because it directly impacts construction processes, from formwork filling to the effective encapsulation of reinforcement.

Balancing Strength and Workability: Achieving the optimal balance between concrete strength and workability is a delicate task. While higher workability facilitates ease of construction, excessive water content can compromise the concrete's long-term strength and durability. Striking this balance is essential for ensuring both efficient construction and a robust final structure.

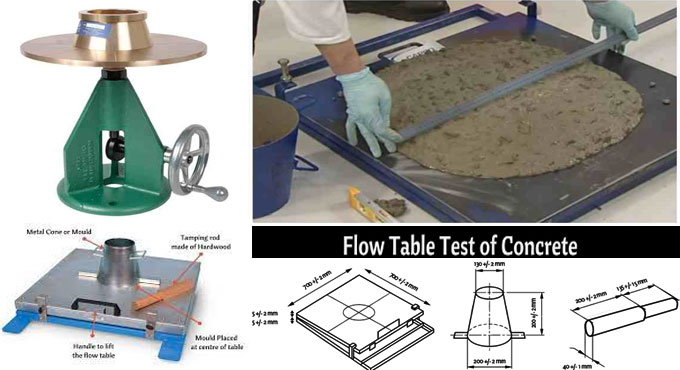

The Flow Table Test Apparatus

Principles of the Flow Table Test:

The Flow Table Test is a standardized method for assessing the workability of concrete. It involves measuring the flow spread of a concrete mix subjected to a specified number of drops on a horizontal table. The diameter of the concrete spread is an indicator of its workability—the greater the spread, the higher the workability.

Components of the Apparatus:

The Flow Table Test apparatus comprises a rigid and non-absorbent table with a vertical guide rod. A mold with a certain diameter and height is filled with the concrete mix, which is then released from a specified height above the table. The apparatus measures the diameter of the concrete spread after a set number of drops.

Procedure of the Flow Table Test

Preparation of Concrete Mix:

The first step involves preparing a representative concrete mix according to the project specifications. This mix typically includes cement, aggregates, water, and any necessary admixtures. The proportions should mirror the intended construction conditions.

Filling the Mold:

The mold is filled with the prepared concrete mix, and excess material is struck off to ensure a level surface. The mold is then placed on the flow table, ready for testing.

Release and Measurement:

The mold is raised, and the concrete mix is allowed to flow freely onto the horizontal table. After a specified number of drops, the diameter of the concrete spread is measured in two perpendicular directions. This measurement provides a quantitative assessment of the concrete's workability.

Calculation of Flow Value:

The flow value, also known as the flow spread, is calculated as the average of the two perpendicular measurements. This numerical value is indicative of the concrete's ability to flow and its workability characteristics.

Factors Influencing Workability in the Flow Table Test

Water-Cement Ratio:

The water-cement ratio plays a critical role in determining the workability of concrete. While additional water may increase workability, it can compromise strength. The Flow Table Test aids in finding the optimal water-cement ratio for the desired workability.

Aggregates and Gradation:

The size, shape, and gradation of aggregates significantly influence the workability of concrete. Well-graded aggregates with a proper mix of coarse and fine particles contribute to improved workability, and the Flow Table Test helps assess this aspect.

Admixtures:

The use of admixtures, such as plasticizers or superplasticizers, can modify the workability of concrete without significantly altering the water-cement ratio. The Flow Table Test assists in evaluating the effectiveness of these admixtures in enhancing workability.

Importance of Workability in Construction

Efficient Construction Practices:

Concrete with adequate workability ensures efficient construction practices. It facilitates easier placement, consolidation, and finishing, reducing the time and effort required for these essential processes.

Optimal Formwork Filling:

Workable concrete can easily fill complex formwork, ensuring that the mold or structure is completely and uniformly filled. This is crucial for achieving the desired shape and dimensions of the final structure.

Enhanced Compaction and Durability:

Workability influences the ease of compaction, eliminating voids and ensuring that the concrete is properly consolidated. Proper compaction contributes to the durability and longevity of the structure.

Minimization of Segregation and Bleeding:

Well-workable concrete minimizes issues like segregation and bleeding. Segregation, the separation of aggregates from the mortar, and bleeding, the upward movement of water in the mix, can compromise the homogeneity and integrity of the concrete. The Flow Table Test helps identify potential issues in this regard.

Consistent Quality Across Batches:

By assessing workability, the Flow Table Test enables the consistent production of high-quality concrete across different batches. This is particularly important in large construction projects where uniformity is essential for structural integrity.

Reduction of Construction Defects:

Inadequate workability can lead to various construction defects, including honeycombing, cold joints, and poor surface finishes. The Flow Table Test acts as a preventive measure by ensuring that the concrete mix possesses the necessary workability for seamless construction.

Quality Control and Mix Optimization

Ensuring Compliance with Specifications:

The Flow Table Test serves as a quality control tool, allowing construction professionals to ensure that the concrete mix complies with project specifications. Deviations from the desired flow value can trigger adjustments in the mix proportions.

Optimizing Mix Proportions:

Through iterative testing, the Flow Table Test facilitates the optimization of mix proportions. Engineers and concrete technologists can fine-tune the mix to achieve the desired workability without compromising strength or durability.

Troubleshooting and Adjustments:

In cases where the concrete mix does not meet the specified workability requirements, the Flow Table Test assists in identifying the problematic factors. Adjustments can then be made to the mix design or construction practices to rectify the issues.

To learn more, watch the following video tutorial.

Video Source: Parag Pal

Workability Assessment for Special Concretes

Self-Consolidating Concrete (SCC):

Self-consolidating concrete, known for its high flowability and ability to fill intricate forms without external compaction, relies on precise workability assessment. The Flow Table Test is particularly relevant for assessing the flow properties of SCC.

High-Performance Concrete (HPC):

High-performance concrete, designed to exhibit enhanced strength and durability, requires a meticulous approach to workability assessment. The Flow Table Test aids in evaluating the mix's ability to achieve both high performance and optimal workability.

Future Trends and Advancements in Workability Testing

Digital Simulation and Modeling:

With advancements in technology, digital simulation and modeling are becoming valuable tools for predicting and optimizing concrete workability. These methods allow for a more nuanced understanding of how different factors interact to influence workability.

Integration of Artificial Intelligence (AI):

Artificial Intelligence is increasingly being applied to optimize concrete mix designs. AI algorithms can analyze vast datasets and recommend mix proportions that achieve the desired workability while considering multiple variables simultaneously.

Sustainability Considerations:

As sustainability becomes a central concern in construction, there is a growing emphasis on developing concrete mixes with lower environmental impact. Future advancements in workability testing may include criteria for assessing the sustainability of concrete mixes.

Conclusion

The workability of concrete is undeniably a cornerstone in the construction industry, influencing everything from efficient formwork filling to the long-term durability of structures. The Flow Table Test apparatus, with its ability to quantitatively assess workability, emerges as an indispensable tool for engineers, architects, and concrete technologists.

As construction practices evolve and the industry embraces innovations, the importance of precise workability assessment remains unwavering. By understanding the principles of workability, leveraging advanced testing methods, and incorporating technological advancements, professionals can continue to elevate the standards of concrete construction. The Flow Table Test, in its simplicity and effectiveness, stands as a testament to the enduring quest for excellence in the art and science of construction.