M25 Concrete Ratio: Everything about Concrete Mix uses and Components

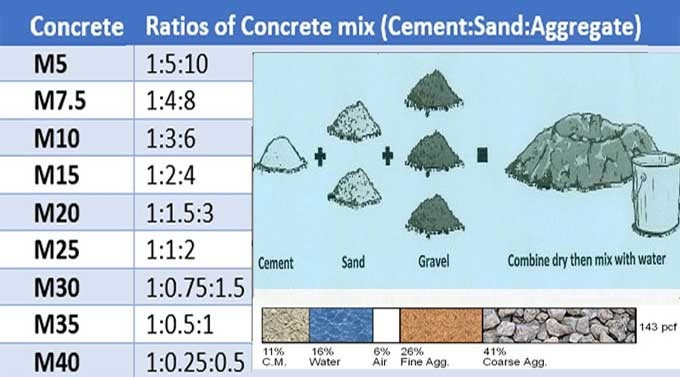

The grade 25 concrete mix helps to reach a strength of 25 megapascals after curing for 28 days. In this type of concrete mix, 1 part of water, 1 part of cement, 2 parts of sand and 4 parts of aggregate have been used, which helps to ensure that this concrete mix achieves great strength for different structural applications.

The use of grade 25 concrete mix is not even overly costly. This grade 25 concrete mix ratio is easy to handle, affordable and has great performance when used in construction projects. In those construction projects which require higher resilience to load, the M25 concrete can be used.

Discuss the M25 concrete strength

After the curing of this concrete mix, impressive strength has been achieved by the M25 concrete, which helps to provide long-term durability to the structural applications. As a result, the M25 concrete is appropriate for those standard building projects where substantial strength is essential.

Different features of the Grade 25 Concrete Mix

Structural integrity of M25 concrete

The M25 concrete mix helps to provide greater structural integrity to the building structure. The M25 concrete mix ratio helps to ensure the bond among the materials used in this mix, which helps to achieve a solid and unified building structure. By using the M25 concrete ratio mix, the structural applications are able to resist stress, as well as having greater load-bearing capacity.

Efficient construction procedure of M25 concrete

The M25 concrete mix helps to reduce the chances of errors during the mixing procedure, which helps to contribute to the smoother workflow in the construction process and also helps to speed up the entire construction procedure.

Cost effectiveness of the Grade 25 concrete mix

The M25 concrete is cost-effective, which helps to keep the construction project i check, thus it is preferred to be used in a wide range of standard construction projects.

Standardisation and compliance of the M25 concrete

The design mix of the M25 concrete complies with the globally accepted standards, thus providing reliability of its expected performance.

The usage of M25 concrete mix

The most common usage of the grade 25 concrete mix is as follows:

Used in slabs

In different types of slabs for building structures, the M25 concrete mix can be used, as this type of concrete helps to provide a solid and flat surface. In this context, the slabs can resist the common loads and ensure their long-lasting performance in both commercial and residential building structures.

Used in driveways

The M25 concrete mix ratio is able to resist the weight of the vehicles, as a result, it is appropriate for the construction of the driveways. The M25 concrete helps to provide a weather-resistant surface, which is capable of bearing the weight and movement of the vehicles, including trucks and cars.

Used in pavements and footpaths

M25 concrete helps to provide safe and long-term, durable footpaths, which can handle substantial foot traffic.

Used in columns and beams

The beams and columns which has been made with the M25 concrete mix have long-term durability and ensure the stability of the building structure.

Used in retaining walls

The retaining walls that are made with M25 concrete mix have the ability to handle the lateral earth pressure.

Used in pre-fabricated structures

The M25 concrete is also appropriate for the construction of the pre-cast elements or pre-fabricated structure, for example, panels, blocks and boundary walls.

Factors that need to be considered while working with Grade 25 Concrete Mix

While working with the Grade 25 concrete mix, several factors need to be considered by the builders, which are as follows:

Quality assurance measures

Proper quality assurance measures should be taken by the builders while working with the M25 concrete. In this context, the builders are required to initiate the quality assurance activities related to the proper design, the design verification of the concrete mix and the usage of the appropriate materials along with appropriate quantity. It also needs to establish a quality assurance plan, which helps to achieve the effective performance of the concrete mix.

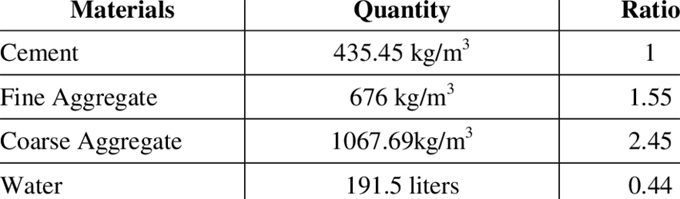

Proper batching process

Proper measuring of the materials and mixing of each material in the concrete mix is necessary to create the standard concrete mix. This batching process has a great impact on the quality of the M25 concrete mix and also improves the workability of the concrete mix.

Following the proper mixing procedure

A mechanical mixture is appropriate to achieve a homogeneous concrete mix. The mechanical mixture helps to mix the concrete for an appropriate duration, which helps to get the proper consistency of the cement.

To learn more, watch the following video tutorial.

Video Source: howYwat

While doing the mixing process, it needs to be ensured that there should not be any lumps, segregation or any kind of dry pockets in the concrete mixture. This process helps to ensure the achievement of uniformity in the production of concrete.