How to repair the Jack Arch Roofing system

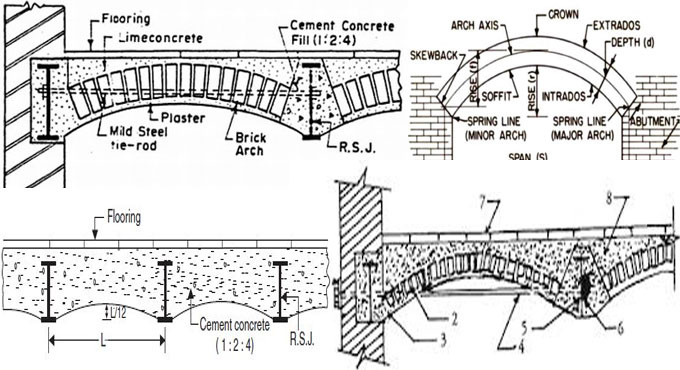

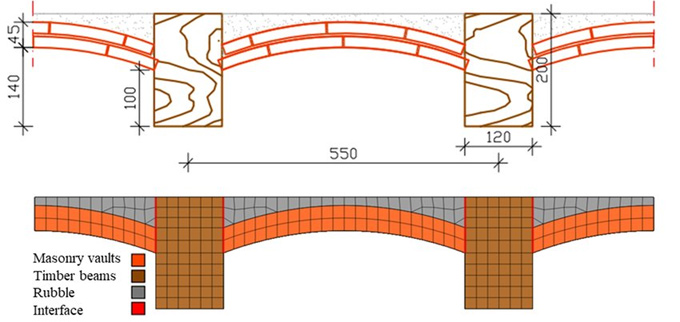

The jack arch roofing involves a series of small sized brick vaults, which are supported on the intermediate beams. In the Jack Arch Roofing system, metal formwork has been placed among the beams and bricks, which have been arranged on top of the formwork. This helps to achieve a shallow vault. This structure has been plastered with cement or lime mortar and waterproofed on top.

After this procedure, the formwork was removed, and the entire procedure was repeated to complete the entire arch. The jack arch roofing system is economical as well as eco-friendly.

The jack arch has been made with concrete or brick. This jack arch roof has been supported on the lower flange of mild steel joists. These rolled steel joists have been supported at their ends on the walls. The jack arch roof system has been spaced at a distance of 1m to 1.5m centre to centre. The rise of the jack arch roof has been kept equal to 1/12th of the span.

Construction of Jack Arch Roof

The jack arch roof has been constructed to be a single course arch. The jack arch has been resting on the brick wall or a steel column. This has been done on the basis of the design and purpose of the building structure. The building load has been transferred in the form of thrust exerted through the arches. The mild steel tie rods have been inserted at a regular distance to balance this thrust. The entire strength comes from the curvature of the jack arches. In this context, the right curvature of the jack arches should be maintained properly.

The construction procedure should be learned properly by the labourers. The formwork for the jack arch roof should be robust, reusable and also easy to handle. The formwork for the jack arch roof can be made with a wooden piece that follows the curvature of the jack arch.

The bottom of the jack arch roof has been connected with the steel joist and this can be done with the help of the clip. This clip has the ability to move the formwork of the jack arch roof back and forth along the steel joist’s length. This helps to make the building process quicker and easier. The lime mortar has been used to fill the gaps between the bricks. A layer of lime mortar has been laid on the side of the jack arch roof. This helps to achieve the flat flooring. The plaster gauge has been used to maintain the thickness. This plaster gauge has been inserted into the wet plaster.

Advantages of the Jack arch roofing system

There is no extra time is required for placing the reinforcement steel or extensive curing, thus making the jack arch roofing system less time-consuming. To achieve a proper curve in the jack arch roof, good care needs to be taken. In this context, the template piece needs to be kept. The steel centering can be used during the casting process and the top arch surface has to be in mud. This helps to achieve the curve as well as helps to ensure the easy removal after casting the roof. For the cross beams, centering support is required. The hole has been punctured in the tiles. This helps to fit the roof boxes correctly. In addition, this also helps to provide the standard wall elbows.

How to repair the Jack Arch Roofing system

The poor quality of the concrete in the jack arch roof and the use of the inappropriate grade of sand led to the leakage in the jack arch roof. In this context, the repair of the jack arch roofing is required. The repair procedure is done in several steps, which are as follows:

1. In the first step, the old cement mortar and tiles have been removed from the jack arch roof. As a result, the new cement mortar has become firm over the rough surface of the roof.

2. In the next step, fresh cement mortar has been laid and left to dry.

3. The waterproofing has been done after drying the cement mortar. This helps to avoid any kind of further leakage. In this context, the waterproofing material has been mixed in a drum of water. This mixture has been splashed over the cement mortar layer. It needs to be ensured that each and every corner of the roof has been covered along with the waterproofing material.

4. Tiling has been done after completing the waterproofing process. This has been done by using a suitable adhesive.

To learn more, watch the following video tutorial.

Video Source: SLV builders