Ribbed and Solid Slab - Types and Benefits of Construction Site

Concept about Ribbed slab

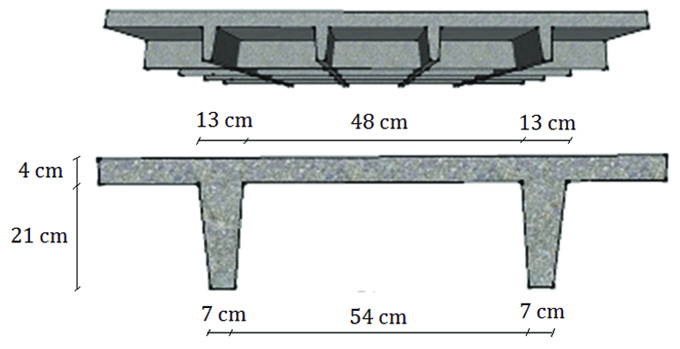

The ribbed slabs are also known as the joist slabs or beam and joist slabs. There are a series of parallel ridges which has been created by constructing the system of ribs underneath the slab. The ribs have been spaced apart at regular intervals, which helps to provide additional support and strength to the slab.

The ribbed slabs are thinner and contain minimal reinforcing. The size and shape of the ribbed slabs vary. The design of the ribbed slabs is lightweight, which is used in those areas that require long spans. The ribbed slab helps to enhance the load distribution capacity of the construction structure.

Different types of Ribbed Slab

One-way Ribbed Slab

A series of reinforced concrete T beams has been used in the one-way ribbed slab, which has been connected with the girders. In these types of ribbed slabs, concrete has been cast among the spacing, which helps to make the ribs of these types of slabs.

Two-way Ribbed Slab

These types of ribbed slabs have been designed to reduce the weight of traditional full-concrete slabs. The two-way ribbed slabs are also known as waffle slabs because of their waffles-like appearance. The ceiling is shown by the two-way ribbed slab, which is appropriate for installing all kinds of electrical appliances. This design feature of the two-way ribbed slab also increases the aesthetics of this type of slab.

Benefits of using a Ribbed Slab at the Construction Site

There are lots of benefits of using the ribbed slabs in a construction site, which are:

➢ The ribbed slabs help to eliminate the stress in the tension side of that slab.

➢ The installation process of the ribbed slab is economical in the case of the live roads that are small, for example, hotels, apartment houses and others.

➢ The ribbed slab helps to construct the long slab spans, which are desirable in the building structure.

➢ The ribbed slabs help to provide more architectural advantages, as in the ribbed slabs, all electrical appliances can be installed more easily, which enhances the architectural aesthetics.

➢ The thickness of the ribbed slab is less than the other types of slabs, which helps to reduce the weight of the slabs.

➢ The ribbed slab also helps to reduce the ultimate load, which reduces the extent of the foundations.

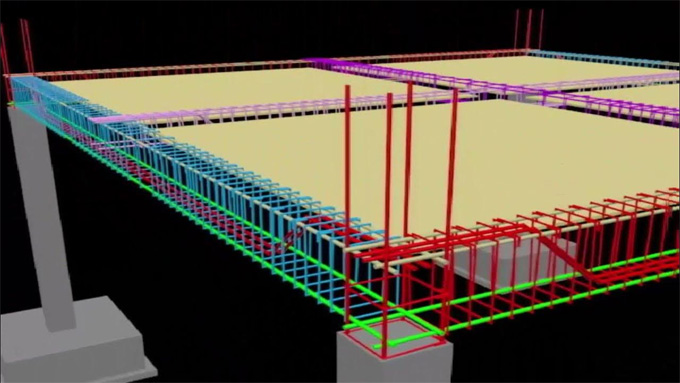

Concept about a Solid Slab

The solid slabs can be 200 mm thick. The solid slabs have been used in areas with short spans, for example, balconies. The production of the solid slabs has been done in several ways, including on a long line or on a table mould.

On the basis of the structural requirements, the size of the solid slabs has been varied.

Application of the Solid Slab at the Construction Site

The solid slab has been used in different types of floors and roofing systems in commercial, residential and industrial buildings.

Benefits of using a Solid Slab in a Construction Unit

There are several advantages of using solid slabs at the construction site, which include:

➢ The solid slabs are perfect for the balconies.

➢ No additional casting is required for the solid slab on the construction site.

➢ The installation procedure of the solid slab is faster compared to the other types of slabs.

➢ In the case of the complicated areas, the solid slabs can be installed.

Process of Constructing a Ribbed Slab and a Solid Slab

There are several steps that have been followed to construct the ribbed and solid slab, which are as follows:

Planning and designing stage

In the first step of constructing the ribbed and solid slab, the span length and load requirements for the slab need to be determined. In this context, the appropriate type of slab should be selected on the basis of the structural requirements. It also needs to ensure that the designs of the slab are compliant with the relevant codes.

Installation of the formwork

In the case of the ribbed slab, complex formwork is required for creating the ribs. In the case of the solid slab, simple formwork is required as it helps to form the flat surface.

Reinforcement placement stage

Steel reinforcement is required to be laid on the basis design specifications of the slabs. In the case of the ribbed slab, additional reinforcement is also required.

Pouring the concrete

In the next step, concrete has been poured to fill the formwork of the slab. In the case of the ribbed slab, it needs to be ensured that the concrete should be flowed into the ribs.

Curing stage

In this stage, the slabs are allowed to be cured for a specific time period, which helps to achieve the slab’s strength.

To learn more, watch the following video tutorial.

Video Source: Danny Engineering

Finishing stage

After the curing process, the formwork has been removed, and the surface finishing procedure has been performed to prevent instability.