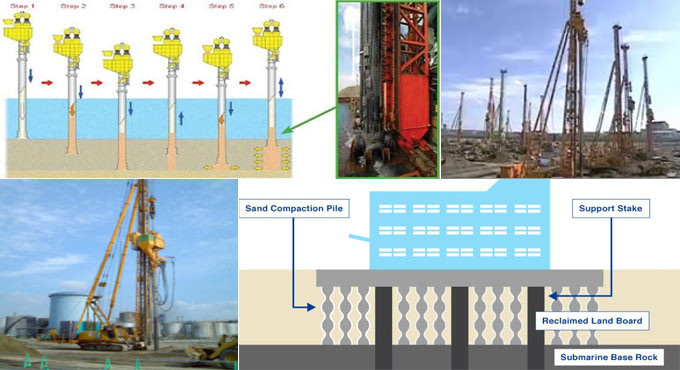

Sand Compaction Pile Method and Its Applications

The sand compaction pile method helps to prevent the liquefaction of the soil, which helps to reduce the settlement of the soil and improve the ground’s stability. In the sand compaction pile method, a hollow steel pipe is driven into the ground and the bottom of the pipe is closed with a collapsible plate. After driving the pipe, it was filled with sand and withdrawn, and this can be done in the meantime of directing the air pressure against the sand. While withdrawing the pipe, the bottom plate of the pipe opens, and the sand helps to backfill the voids.

This procedure helps to prevent the collapse of the soil that surrounds the compaction pipe. The sand compaction pile method depends upon the stability of the sand column. This method also depends upon the pile and the soil, which are subjected to equal vertical deformation.

In general, two types of sand compaction pile methods are available, for example, the vibratory sand compaction system and the non-vibratory sand compaction system. The usage of the vibro-hammer has been seen in the case of the vibratory sand compaction pile method. On the other hand, there are no requirements for any vibration on the driving device in the case of the non-vibratory sand compaction pile method. In this case, the sand compaction pile driving devices have been used along with a rotatory drive motor, which helps to rotate the casing pipe.

Implementation of the Sand compaction pile

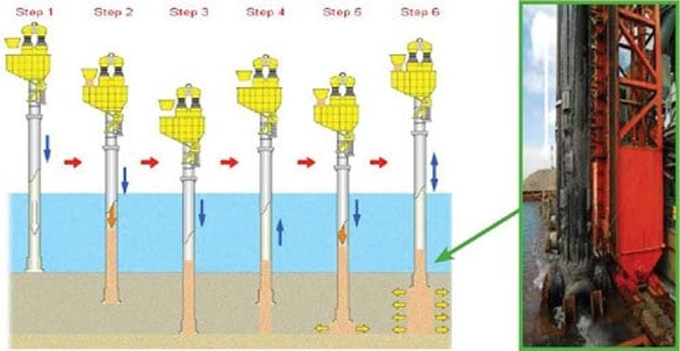

The sand compaction pile has been done by following several procedures, which are as follows:

Positioning stage

In this stage, the casing pipe is set at the predetermined place in the ground.

Casing pipe penetration process

After positioning the pipe, it was penetrated into the soil with the help of the vibrator.

Feeding sand process

After the penetration procedure, the casing pile has reached the specific depth that has required. In this context, feeds sands into the casing pipe, and this can be done with the help of the upper hopper.

Drawing up the pipe

In the next step, the casing pipe is being drawn up, which leads to the forced out of the sand throughout the void by the application of the compressed air pressure.

Re-driving the pipe

The casing pipe has been re-driven while the sand pile has been pressed out because of the vibration.

Completion of the method

The entire procedure of compacting the sand pile to the reach of the pipe into the ground surface has been repeated.

Discuss the advantages and disadvantages of the sand compaction pile

There are numerous advantages and disadvantages of using the sand compaction pile method. The advantages of this method include:

➢ The sand that has been used in the sand compaction pile method is relatively cheaper than stone or other materials.

➢ In the sand compaction pile procedure, the sand column construction procedure is fast, which enhances the first completion of the entire sand compaction pile method.

➢ The hole in the sand compaction pile method has been supported by the casing pile during the construction process. This helps to eliminate the chances of hole collapse.

➢ In the case of the sand compaction pile method, there is less chance of surrounding soil erosion or soil intrusion into the sand column. This reduced erosion chance is relatively higher than the stone columns.

➢ The sand compaction pile procedure helps to strengthen the previous embankment foundations, which are prone to liquefaction or any kind of stability problems.

➢ The load-bearing capacity of the soil has also been improved by applying the soil compaction pile method.

Apart from the advantages, there are several disadvantages of using the sand compaction pile method, which include:

➢ In the sand compaction pile method, there is a lower angle of internal friction as compared to the stone column. In addition, there is lower stiffness in the sand column as compared to the stone column. In this context, a larger amount of weak soil needs to be replaced while applying the sand compaction pile method.

➢ The driving of the casing pipe by using the clay layer leads to the smear along the column boundary. This process leads to the reduction of the lateral amiability.

➢ The sand compaction pile method does not provide sufficient permeability to perform in the case of an earthquake.

➢ The application of the sand compaction pile method helps to enhance the density of the previously native soils around the piles. In this context, the improvement occurs depending on the spacing of the pile and the methods of construction.

To learn more, watch the following video tutorial.

Video Source: Danah Al-Enezi

In addition, the strength of the sand compaction pile method helps to enhance the failure resistance, which leads to the occurrence of liquefaction.