Everything you need to know about Asphalt Flooring

This floor is waterproof, anti-skid, junction-resistant, water-resistant, appealing in appearance, and acid-resistant. It is also junction and junction resistant. A flat covering known as asphalt flooring is created by mixing paint, glass beads, chrysotile, asphalt, and colour.

It is usually flat, approximately 1/8 to 3/16 inches thick, impenetrable, flameproof, inexpensive, and simple Linoleum takes less time and is virus-resistant, acidic, and oil- and animal-resistant, however asphalt flooring will grow for humid and fundamental rules. Where the floor climate is less than 80 degrees Fahrenheit, it is applicable.

Where is flooring made of asphalt used?

Asphalt flooring is used in parking lots, flyovers, footbridges, verandas, and other structures. It may be applied most quickly to an existing concrete base. Therefore, opening up patios and footbridges is beneficial. Asphalt flooring is preferred by most nations due to its hardness and longevity. The garage, flyover, sidewalk, runways, etc. are only a few places where asphalt flooring is advantageous.

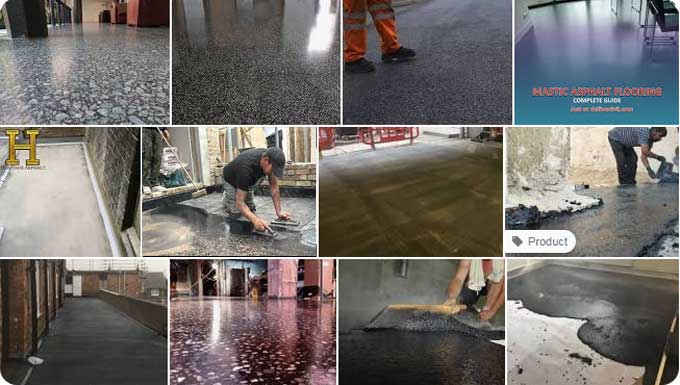

What is Asphalt Mastic Flooring?

Mastic asphalt flooring is gaining popularity these days due to its dustless, elastic, strong, waterproof, acid-proof, and appealing look. Mastic asphalt flooring is suggested for use in industries, loading docks, swimming pools, terrace floors, etc. since it is non-slippery and noiseless. The following activities are necessary for floor construction:

1. The preparation of asphalt mastic flooring.

2. Preparation of compost (mastic asphalt) for laying.

The preparation of asphalt mastic flooring

Before installation, the old floor has to be cleaned and the cement, sand, or other materials separated. To help you separate the old asphalt, you will need a lot of equipment.

Set the lean to insure appropriate wastewater after cleaning. A precise pour will help prevent your flooring from settling too soon. The water drains through the floor and pools at the edge.

It is essential to install a sub-base since it will provide a solid foundation and core support system for the flooring. The sub-base acts as an ice bridge in the cold, reducing fractures from frequently difficult defrosting.

Once the sub-base is compressed and configured, it is time to demonstrate the roll. Proof rolling makes sure that the fundamental design is secure to support the asphalt and load.

The folder layer needs to be included. Having recovered the sub-base and smooth zone of the base, it's now time to configure the folder base. As part of the process of strengthening your asphalt and making it durable and long-lasting, the binder layer will be able to combine ingredients and oil to make it as tough as possible.

Last but not least, the new asphalt flooring needs to be installed. As a result of sand, oil, and other microscopic particles, the illusion of complete darkness is created. The flooring is soft and lovely when it is laid correctly, as well as providing an attractive surface.

As you may have already noticed, your new asphalt joints will be the last phase of your project. This is because you want to be able to travel easily from the parking lot to the highway and from the pavement to the parking lot.

Merits

1. Bitumen will be applied to surfaces through asphalt flooring to provide an additional damp proof basis.

2. By installing asphalt flooring in a parking lot, the long-lasting and durable design will be made available. Asphalt roadways will give analysis for their strength and durability.

3. Because of its construction, asphalt flooring as a size inhibits the debris from joining with concrete flooring.

4. By applying an asphalt flooring base on top of your floor, you will be able to eliminate certain things that are hurtful to the floor, like rough edges.

5. An asphalt walkway balcony looks fantastic in the practical and long-lasting flooring of a home.

6. She was presenting a crooked end that highlights the duck's inclination. Asphalt will replenish material, and because of its endless duration, you may apply it more than once.

7. When it comes to healing, asphalt is rational and uncomplicated; if you supply asphalt, less attention will be required.

Demerits

1. Concrete is less delicate than asphalt flooring, which needs to be sealed off every 4 to 5 years to keep it from cracking after being plastered. Sometimes you don't have to take the flight.

2. Asphalt will consume if it is not properly varied and positioned, and before installing flooring, you may keep old and damaged planes.

To learn more, watch the following video tutorial.

Video Source: MFA Civil Engineering

3. It should be heated to between 250 and 350 degrees F if you want a great solution. Prior to the plane's asphalt flooring, you must cover it with sand or other materials to acquire greater compression and a durable lifeline.

4. Later, fuel will be used to make asphalt, which causes damage when organic components are removed. Reversal asphalt will then be used to make asphalt concrete that is free of further organic compounds.

5. Without carpeting hardware, you will not be able to install asphalt flooring, which requires a tracked vehicle to build.

6. Asphalt flooring needs a tracked vehicle to construct, and without flooring hardware, you will not be capable of installing the asphalt.