How to Design a Concrete Box Culvert

The Box Culvert refers to the precast concrete structure which has been used to channel water. The box culverts have been used under the road or railway bridge, in which a stream has been crossed with a restricted flow.

There is no requirement to construct separate foundations for the box culverts, as the bottom slabs of the box culverts have acted as the raft slab and can rest on the ground directly. The concrete bottom of the box culverts enables the free flow of water. During the construction procedure of the box culverts, reinforced concrete has been used.

Discuss the different types of Box culverts in construction

Numerous box culverts have been used in construction work, which can be differentiated according to their own purpose and unique designs. The most common types of box culverts are as follows:

Precast box culverts

The precast box culverts can be made of precast concrete, which is able to create a continuous structure. These types of box culverts have been widely used in construction sites.

Arch box culverts

These types of box culverts have an arch shape on their top, which helps to provide additional strength and stability to the construction structure.

Three-sided box culverts

These types of box culverts have three sides, which can be used for shorter spans, as well as help to minimise the flow rate of the water.

Double box culverts

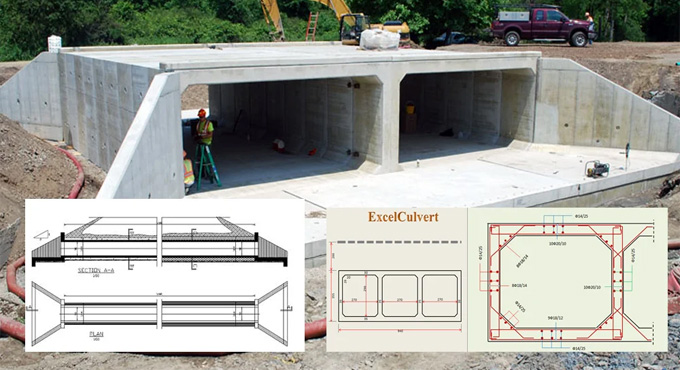

In the double box culverts, there are two box culverts which has been placed side by side along with a common wall in these types of box culverts. These common walls help to separate the two box culverts of these types of box culverts. This design helps to enhance the flow capacity of the water. In addition, the design of the double box culverts also helps to provide the necessary support.

Concrete box culverts, along with steel reinforcement

These types of box culverts have been reinforced with steel, which helps to provide long-term durability and additional support to the construction structure.

Cast-in-place box culverts

The Cast-in-place box culverts can be customised as per the design requirements of the construction work, and can also increase flexibility in the construction process.

Discuss the effectiveness of the Box Culvert in construction

The box culverts have versatile uses in the construction site, which are as follows:

Used for bridging

The box culverts have been widely used for bridging purposes, which enables the construction of roads and train tracks. The box culverts also help to construct bridges across the creeks and streams, which enables the free crossing of livestock and other wildlife.

Used for the drainage system

The precast box culverts are appropriate for use in the drainage systems as these types of box culverts enable the proper operation of the stormwater drainage system, thus helping to prevent the risks of flooding.

Used for industrial purposes

The box culverts have been utilised for the house's electrical cables or as the water, steam or air ducts. In addition, the box culverts have also been used as emergency escape routes in several circumstances.

Process of designing a concrete Box Culvert

Several process needs to be followed while designing the box culverts, which are as follows:

➢ In the first step of designing the box culverts, the design loads should be determined, and this can be done by applying the suitable partial factors to the applied loads.

➢ In the next step, the box culverts have been considered as the rigid frame, which helps to determine the shear forces, bending moments and the axial forces in the culvert walls and slabs.

➢ The axial forces have been used to estimate the amount of steel which has been required in the culvert slabs and walls.

➢ In the next step, it has been verified that if the shear reinforcement is required or not, and also it is ensured that if section thickness should be increased or not.

Learn about the benefits of using the Box Culvert in construction

Providing structural strength

The box culverts have higher strength and durability, which can be used in harsh environmental conditions.

Easy to install

The box culverts are easily and quickly installed as it has been prefabricated off-site, and after that, they have been transported to the construction site. Thus, the overall time and cost regarding the construction work have been minimised by installing the box culverts.

Required low maintenance

The box culverts have been designed to last for a longer period of time with low maintenance. Several environmental hazards, including corrosion, chemical degradation and others, can also be resisted by the box culverts.

To learn more, watch the following video tutorial.

Video Source: Civil Engineer - Ishaq Sohag

Versatile design availability

The box culverts have been available in different sizes, angles and shapes, which can be easily fitted in different types of site conditions.

Environmentally sustainable

The box culverts have been made with concrete, which is sustainable for different kinds of environmental conditions.

Increasing flow capacity

The flow capacity of the box culverts is higher compared to the other types of drainage structures, which are able to manage the higher volumes of water, thus reducing the risks of flooding.