Tips for minimizing the Environmental impact of Concrete Construction

Builders are reimagining how projects are conceptualized, designed, and executed as we move beyond traditional construction methods. Scientists are working on ways to conduct energy in bricks and pavement using cigarette butts, while paint developers are rethinking chemicals for more energy efficient homes.

Additionally, recycled glass, drywall, and steel, as well as renewable resources such as bamboo, are becoming more popular. Businesses pay less than two percent more on average for green building features. Over the life of the building, they're expected to recoup seven times that initial investment.

Key Methods for making your concrete Eco friendly

Lightweight Concrete Mix

In comparison to regular concrete, lightweight concrete has a different composition. Low density and high strength are achieved by using lightweight coarse aggregates in the mix. Their recycled content and natural materials help reduce CO2 emissions and energy consumption, further reducing CO2 emissions.

Buy Materials from Local Supplier

It is best to choose a local supplier so that transportation has a less harmful effect on the environment. Look for companies that transport via rail or ship, as these methods emit less CO2 than trucks if you don't have any local options.

It is important to remember that frequent, short trips can have a major impact. By purchasing multiple materials from the same company or picking up all your supplies from the same place, you can reduce the number of trips you make to pick up supplies.

As you can see, there are many variables to consider. Your unique project needs and location will ultimately determine the best option.

Recycled Concrete

It is possible to create a lot of waste when an old concrete building is demolished. It is now possible to recycle concrete in an easy and well-researched manner. It is possible to break down old, large pieces of concrete into coarse aggregates.

Rather than using virgin aggregates, you can use recycled coarse aggregates in your mix design. Crushed coarse aggregate can be replaced with coarse recycled aggregate up to thirty percent if natural sand is used. You can reduce the impact of mining new aggregates by using recycled concrete in your mix design.

Fresh Concrete

Fresh concrete leftovers can be reused in a new batch of ready-mix concrete instead of sending them to landfills. This specification covers the measurements, verifications, and uses of returned fresh concrete to make a new batch of ready-mixed concrete.

Participation in this process prevents usable concrete from being disposed of in landfills. It is important to remember that fresh concrete is usually only good for 90 minutes after pouring. If you have leftover fresh concrete, take it back to the manufacturer as soon as possible. Concrete construction can be made more environmentally friendly by using this method.

Carbon Cure Solution

In order to make concrete more sustainable, Carbon Cure works with concrete producers. With their unique technology, industrial emissions of CO2 are injected into concrete and chemically converted into minerals. As a result of the mineralized CO2, concrete performs better and has a greater compressive strength, making it a more sustainable and safe construction material.

Wrapping it Up

Concrete construction plays a major role in building efficiency, reducing construction costs, and improving safety and quality. In order to reduce carbon footprints and improve cost efficiency, new materials are needed, such as 3D printing and self-healing concrete.

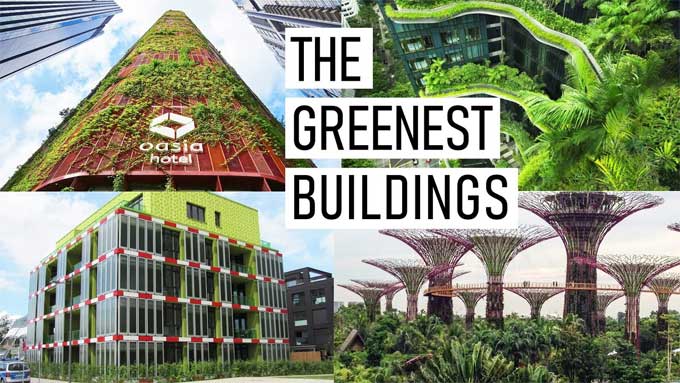

To learn more, watch the following video tutorial.

Video Source: Going Green

Buildings that generate as much renewable energy as they consume within a year are driving much of the demand for new materials. Buildings that use solar panels or wind turbines are designed to consume as little energy as possible.