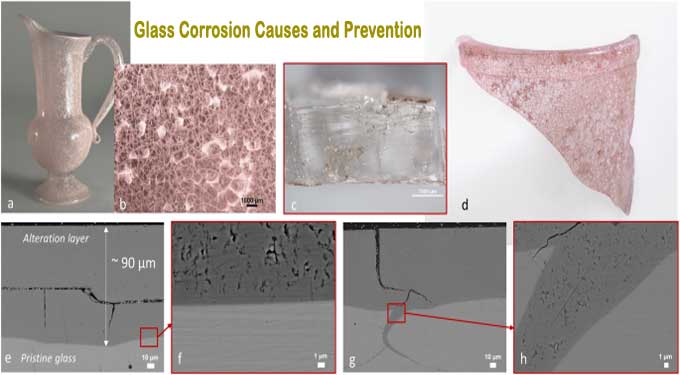

The Ultimate Guide to Glass Corrosion Causes and it?s Prevention

Architects and builders have long recognized the durability of glass in architecture and construction. Water, heat, and humidity can cause staining or corrosion depending on how severely the glasses are exposed to contaminants. Glass corrosion occurs when water or chemicals react with the contents of the glass, leaving behind residues that appear as stains on the surface.

Glass fabrication and installation may be hampered by improper storage, which may lead to glass corrosion. Glass handlers can find the best way to prevent staining or corrosion by determining the circumstances under which the glass is subjected.

Glass Corrosion Main Causes

Prolonged exposure to water or chemicals causes severe chemical reactions on glass surfaces. A soda-lime-silica glass combination reacts with the water present on its surface. The corrosion and stains are the results of the interaction, which is subtle and slow. Several chemical reactions lead to glass corrosion.

Diffusion

Ion exchange is controlled by diffusion, which causes glass corrosion. One ion of sodium reacts with one ion of hydrogen from the water in this reaction. A sodium ion is dissolved in water as a result of this process. A reaction occurs in which hydroxide ions accumulate on glass surfaces, increasing the PH.

When PH Level< 9

Under typical conditions, this corrosion would continue for as long as the pH is 9. Glass remains undamaged during this period regarding both optical quality and surface integrity. Alkalinity increases with PH. Furthermore, excessive alkalinity on the surface of the contact induces more damaging reactions. It is therefore important to examine closely the leaching observed on glass surfaces.

When PH Level>9

PH levels of 9 or higher trigger the reaction of Glass Corrosion. The pH level at this point is enough to damage glass silicate networks. The first signs of this reaction include microscopic pits.

The surface damage of Glass increases as the reaction progress. However, even when the integrity of the glass remains intact, this stage affects its optical quality. Carbon dioxide in the atmosphere can also react with the moisture on the glass surface, forming surface residues such as sodium and calcium carbonates.

How to prevent Glass Corrosion

1. Cleaning and drying the surface of the glass can prevent corrosion. The glass surface also remains protected when a corrosive environment is avoided.

2. Chemical cleaners and improper cleaning procedures should be avoided.

3. Prevent abrasion and mechanical damage to glass surfaces by ensuring that they are interleaved with paper or powdered interleaf materials. By neutralizing and controlling pH, the interlacing system prevents glass corrosion.

4. Glass Corrosion occurs when the surface of a glass is washed away by corrosion. A combination of high dishwasher temperatures and long wash cycles, poor glass quality, and soft water cause corrosion on the glass. Based on the application, choose the right type of glass.

5. Employ anticorrosive glass in environments with high humidity, such as bathrooms.

Wrapping it Up

As part of the last rinse cycle, your dishwasher adds a rinse aid to make sure that water drains completely from your glasses for brilliant and spotless drying. For perfectly sparkling results, refill the rinse aid dispenser when necessary to neutralize soap residue and prevent lime scale deposits. If you must wash your glasses, do so gently and softly. 40-degree Centigrade temperature delicate provides hygienic results and optimal care by preventing cracking.

To learn more, watch the following video tutorial.

Video Source: drweigert

Dishwashers are especially prone to breaking long-stemmed glasses. If the stems fall over when being washed, they can easily break. A Glass Secure Tray offers the best protection against breakage as well as scratches, so you must purchase one to keep your valuables safe.