Everything you need to know about Concrete Batching

In general, concrete is a versatile, environmentally benign building material that is extensively employed in most construction across the globe. Additionally, concrete is a cheap material.

Currently, this sort of material has to be prepared, but if you want to make high quality, you must take into account all the components with the necessary amount to achieve an exact result; this procedure is known as batching.

Water, aggregate (whether fine or coarse), and cement are the main ingredients of concrete. Cement serves as the adhesive in this situation. You must manage the quantity of water used as well as the ratio of cement to aggregates if you want to produce cement batching.

What do you mean by Concrete Batching Plant?

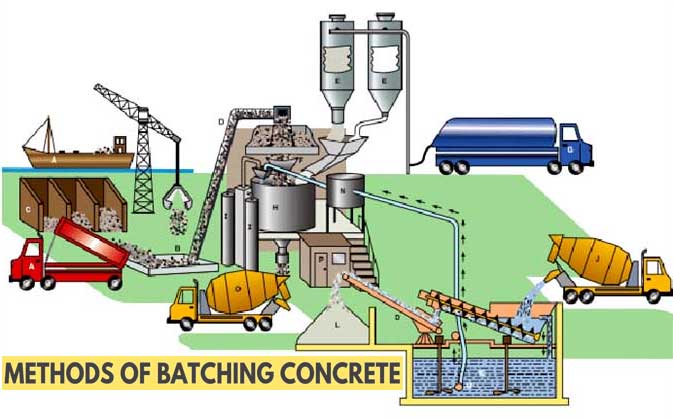

A concrete batching plant is a particular kind of facility where various components are mixed to create concrete. Cement, sand, aggregates, water, admixtures, silica fume, fly ash, slag, and other diverse components are employed.

Mixer, aggregate and cement more batches, aggregate bins, conveyors, cement bins, heater, radial stackers, chillers, dust collectors, etc. are some of the different types of components found in batching plants.

Screw conveyors are used to gathering all the aggregates, and a control system is used to regulate the entire operation. The mixing process will then be finished, and concrete will be ready.

What is actually the Batching of Concrete?

Batching of Concrete refers to the process and method of batching concrete, which refers to the estimation of the number of materials to be mixed and mixing them by volume and weight in order to maintain a consistent quality of concrete throughout the batching process.

In the concrete batching process, precision is one of the most crucial parameters. This process of batching concrete by volume is generally preferred over weight batching when it comes to concrete because it is more accurate. Before mixing begins, the aggregates and concrete materials are properly batched, and we get a proper batched concrete that is accurate and well-batched.

The concrete batching process generally helps to increase the practicality of the construction due to the fact that it helps to produce a smooth surface and speeds up the construction process since the volume of the concrete is reduced when properly batching. Concrete batching is one of the most important processes for the production of concrete.

Varieties of Batching of Concrete

There are three different varieties of Batching of Concrete:

Volume Batching of the Concrete

Another method of mixing concrete is called volume batching, which employs measuring boxes, often referred to as "gauge boxes" or "farms." Typically, the volume of "farma" is 35 trash or the equivalent of one bag of cement. Farmers then measure out all of the coarse and fine aggregates, and when everything has been correctly mixed, the project is complete.

Following that, water is added, and volume batching is used to make cement.

Random Volume Batching of Concrete

There is no proportion of cement, aggregates, water, etc., when random volume batching of concrete is used. As a result, the concrete can not achieve its desired strength, because it has created an error in the concrete.

Due to the random use of different containers by the workers and because of the non-consideration of the number of containers, the number of materials cannot be controlled. The reasons for this are that the workers randomly use different containers.

In medium-type construction, it is not allowed to use this method since it is unscientific.

The Weigh Batching of Concrete

Another method of concrete batching that is widely used on construction sites is the weight batching of concrete, which is another method of concrete batching. We weigh all the aggregates and cement in this weighing machine, which is called a weight more batch machine, and the scale we use to do this measurement is called a scale. The process of weight batching is very accurate, simple, and easy one to understand and apply. It is for this reason that everyone tries their best to adopt this practice.

It is necessary to use different types of weights and batches of cement depending on the type of construction work that is going to be carried out. In terms of weight watchers, there are three types available, namely a manual more batch, a semi-automatic more batch, and a fully automatic more batch. All of these steps are followed by the addition of water, followed by the batching of concrete by weight.

To learn more, watch the following video tutorial.

Video Source: Civil Mentors

Varieties of Concrete Batching Plants

The Semi-Automatic Weigh Batching Plant

There is another type of batching plant called the semi-automated weight batching plant, and in this type of batching plant, the gates of the aggregate bins are operated manually.

Automatic mixing takes place during the delivery process, and the gates will automatically close after the delivery process is completed.

The Fully Automatic Weigh Batching Plant

It is thought that the fully automated weigh batching plant is the most modern and widely used type of batching plant in the modern age. An automated system is one that needs to be deployed by experienced and trained engineers, and it is an automated system.

The batching system for a fully automated weigh batching plant is controlled by an automated microprocessor that is controlled by a microcomputer.

Furthermore, the moisture content of aggregates is also measured automatically in this system, and in case there are any changes in the moisture content, relative measurements will be taken to determine the desired strength for the concrete.

The Manual Weigh Batching Plant

As far as batching plants are concerned, the manual weight batching plant is the first type of batching plant that was used in the past. Plants of this type are very time-consuming to maintain, and the proportion is not well maintained in this type of plant.

The aggregates are mixed manually using the manual weight batching process in the manual weight batching plant. In the case of small type construction projects, a manual weight batching plant is used for the purpose.