Everything you need to know about Pervious Concrete

A key component of structural strength and essential building material is concrete. By virtue of its name, we automatically assume that concrete must be impenetrable, leak- and damp-proof, and strong enough to support the load. Concrete must be impermeable to water since, in RCC constructions, it will cause steel to corrode.

As a result, the name "pervious concrete" is misleading and unclear. So why should previous concrete be utilized? We are talking about previous concrete here. Yes, at first glance, concrete and that transparent material seem inappropriate and nonsensical.

The concrete industry does, however, employ one significant environmentally friendly substance as an eco-friendly industrial practice for tackling pollution control, stormwater management, and sustainable design.

Cement, coarse aggregates, water, and, if necessary, admixtures and other cementitious ingredients, make up the unique form of concrete known as pervious concrete. No fine aggregates, which are typically employed in the concrete matrix, are present in this form of concrete.

Because there are more vacant spaces in the material, water may move more easily through it. As a result, pervious concrete is also known as porous concrete or permeable concrete.

Open cell structures made of porous concrete enable rainfall to permeate the pavement and seep into the underlying soils. In other words, the environment and pavement surface on which it rests are both protected by this concrete.

The same components that go into making regular concrete also go into porous concrete. A network of linked voids that make up 15?30% of its volume allows water to travel through the concrete.

Applications of Pervious Concrete

1. Low-traffic pavement

2. driveways, lanes, and roads in residential areas

3. paths and sidewalks

4. places for parking

4. low-water bridges

5. courts for tennis

6. underpinning for traditional concrete pavements

7. stability of slope

8. linings of wells

9. hydraulic systems (where permeability is accepted)

10. Decking of swimming pools

11. sidewalk tree grates and pavement edge drains

12. Seawalls and groins

13. acoustic barriers

Characteristics of Pervious Concrete

1. The normal concrete pavement system is 143 liters per minute per square meter permeable.

2. The steady-state infiltration rate of the soil, on the other hand, varies between 25 mm/hr and 0.25 mm/hr.

3. The density of the concrete affects its strength and permeability. With more consolidation, but at the expense of permeability, strength can be increased.

4. Porous concrete's typical flexural strength ranges from 1 MPa to 3.8 MPa.

5. The w/c ratio and compressive strength of traditional concrete are significantly correlated. The paste may flow from the aggregate and fill the void structure as a result of a high w/c.

6. Reduced adhesion between aggregate particles and placement issues may be caused by a low w/c.

Advantages of Pervious Concrete

There are many advantages to using pervious concrete, including:-

1. Enables subsurface aquifers to be refilled.

2. It avoids ponding and flooding issues by allowing rainfall to seep into the ground.

3. Protects downstream natural water bodies by preventing stormwater runoff from leaving the property.

4. Helps clean stormwater by removing impurities including silt, germs, and pollutants.

5. It could aid in lowering the Heat Island Effect, which is frequently linked to sizable impermeable surfaces.

6. reduces the need for costly stormwater management techniques, including retention ponds, especially in metropolitan areas where land is expensive and scarce.

Drawbacks of Pervious Concrete

1. It is possible that inadequate maintenance might lead to badly congested pervious concrete. The permeability of porous concrete won't likely be impacted, though.

2. Using good curing techniques and an appropriate water-to-cement ratio can reduce abrasion and raveling.

3. The presence of some loose stones on a finished pavement is to be expected, but raveling of a severe nature should be avoided.

4. Concrete placed in full saturation would experience extensive freeze-thaw cycles at very low temperatures if exposed to very low temperatures.

To learn more, watch the following video tutorial.

Video Source: Pervious Products

Mixture Designs

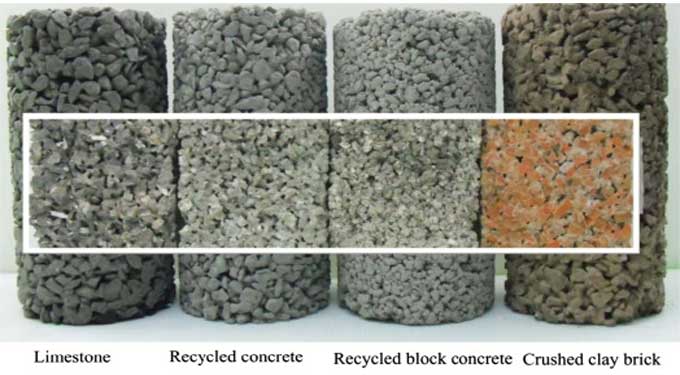

Concrete that is soluble in water is made with the same materials as conventional concrete, except that little or no fine aggregates are used in permeabilized concrete. As a result, three inches of coarse aggregate are used as a construction material for minimizing surface roughness and for improving aesthetics.

Among the types of cement that can be used in the production of water-permeable concrete are ordinary Portland cement and blended cement. There are also various chemical additives that can be used in porous concrete, such as water-reducing admixtures and concrete retarders.