What is Pre-packed Concrete and how does it work?

Pre-packed concrete is a type of concrete that is mixed and packed in a factory before being delivered to the construction site. It is a convenient and efficient way to get concrete, and it can be used for a variety of applications.

Concrete is a versatile and durable material that has a wide range of applications in construction. It is used to create foundations, floors, walls, and other structures. Concrete is also used in the creation of bridges, dams, and other infrastructure.

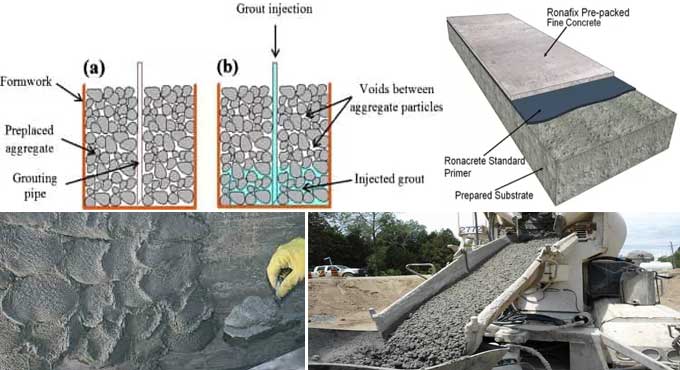

In general, concrete is made by mixing all the ingredients in a mixer. Concrete members can also be fabricated by placing coarse aggregates in a mold and then grouting with a specially prepared mortar. As soon as the concrete is mixed, it is placed in formwork. As a result, this is done for both reinforced concrete and plain concrete.

Pre-Packed Concrete Construction Process

A normal method of concreting may disturb pre-planned fittings. Whenever reinforcement is complicated & the concrete must incorporate certain arrangements such as pipes, conduits, openings, & other arrangements, this method of concrete construction is used.

One of the practicable methods of concreting underwater involves placing aggregate in water and then grouting in mortar to dispense with the water. In addition to mass concreting, bridge abutments and piers, well staining, and other applications, this method is also used.

There are many proprietary methods in vogue at the moment. There are various types of grouting, including intrusion grouting, grouted concrete, pre-packed concrete.

Pre-Packed Concrete Requirement

Filling the voids and developing a full bond between the grout and aggregate are the essential requirements. It is important to apply the right amount of pressure so that the grout fills the aggregates but does not disturb or lift them up.

Additionally, sometimes expandable admixtures such as aluminum powder are added. According to the depth at which the grout is injected, the grouting pressure changes.

1. In underwater grouting, a critical property to look for is the grout's fluidity & ability to keep its identity while pushing water out. It is essential that the grout mixture be sufficiently fluid to pump.

2. Colloidal grouts are suspensions of fine particles in water with a special binder. When mixed in a high speed machine, the binder and water work together to create a fairly thick, pump able consistency.

3. The mixing process is important because it ensures that the mortar grout is the correct consistency. If it is too thick, it will not flow properly & it is too thin, and it will not be able to support the weight of the concrete.

4. Mixers work by quickly agitating the ingredients together to produce a more fluid mixture than what would be possible with manual mixing. The mixer's high speed helps to create a more intimate mix, which is more effective than normal grout.

Grouting Method

Packets of aggregate are poured with a grout mixture, which penetrates downward. A thin concrete member, such as a pavement slab or a floor slab, is typically reinforced using this method.

Construction Method Requirement

Grout cannot be assumed to have completely traversed the entire thickness of the aggregate bed if the bed depth is greater. That can cause problems with the structural integrity of the concrete and is something that needs to be taken into account when choosing this construction method.

Grouting needs to be done with care to avoid any issues. If grouting is not done properly, it can lead to aggregate floating on the surface, which can lead to problems with the structure of the building.

Construction Process

The process of deposition of concrete onto the mold is known as casting. The mold is first partially filled with grout, which helps to distribute the concrete evenly over the mold. The concrete is then vibrated to help settle it into the mold and remove any air pockets.

Workflow

Grout is a fluid concrete that is used to fill voids in masonry. It is injected into the concrete through a pipe with holes in it. The pipe is withdrawn as the grout is injected so that the entire depth of the concrete is filled. The grout should be injected with less pressure into the top layers of concrete.

To learn more, watch the following video tutorial.

Video Source: American Concrete Institute

Uses

This method is often used when grouting large areas or when grouting in difficult-to-reach places. The repacked aggregate can be embedded in perforated horizontal pipes at different levels. In some cases, grout can be transported through these pipes.

Demerits

Withdrawing the pipe provides an opportunity to inspect the pipe's inside for any debris that may have become lodged during installation. If the pipe is left in the concrete, it is more difficult to inspect and clean.

In other words, if the grout is forced into the aggregate too quickly and without taking into account the pressure that the aggregate is already under, it can cause the aggregate to become dislodged and result in the grout being wasted. That can be a big problem because it can lead to using too much grout and not having a strong foundation.

Benefits of Pre Packed Concrete

Some of the advantages of pre-packed concrete are that it can be less susceptible to drying shrinkage, as the aggregate is in point contact with each other and the grout only fills the voids. This can also make the concrete vibrate less before grouting, making the quality of concrete better. Additionally, both single sized and graded aggregates can be used without much difficulty.