Applications of Prestressed Concrete

Prestressed concrete is versatile to a wide assortment of auxiliary frameworks. These incorporate pretensioned and post-tensioned structures, both cast set up and precast, and other prestressed elements related to ordinarily strengthened concrete.

While there is no broad order for precast and prestressed concrete, it is helpful to aggregate certain elements and structures to clarify how prestressed and precast concrete is planned and developed.

Types of Prestressed Concrete - Prestressed and precast concrete might be considered in four general classifications:

1. Standardized Elements

2. Fixed Cross Section Elements

3. Completely Engineered Elements

4. Precast Nonprestressed Elements

While there is some cover, each gathering has its own special attributes.

The job of the engineer differs with the sort and intricacy of the auxiliary framework being built. To be sure, numerous engineers might be associated with some part of the structure, creation, and development of the task. As a rule, the structure engineer who is commonly the authorized plan proficient or engineer of record is liable for the general structure.

The extraordinary attributes of prestressed concrete regularly require the extra administrations of a claim to fame as an engineer. The strength engineers can either give counseling administrations to or be utilized by a precast plant or contractual worker. Forte engineers can likewise be related with post-tensioning organizations either as a worker or expert.

In either case, the forte engineer takes the idea arranged by the authorized plan proficient and gets ready last point by point structure figuring just as creating manufacture or development subtleties important to finish the undertaking.

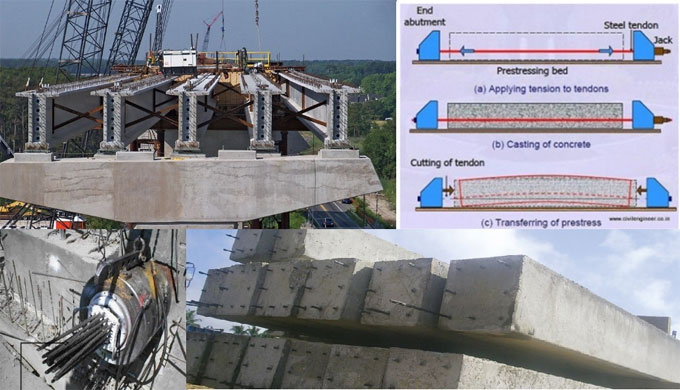

Standardized Precast Prestressed Elements: Pretensioned concrete shafts and chunks are regularly developed in reusable steel shapes in a precast plant. Albeit an unassuming measure of custom formwork is utilized at precast plants, improved quality and decreased expenses are acknowledged just when Standardized elements are utilized.

They comprise standard segments, for example, single-T and twofold T bars, box supports, hollow core sections, rearranged T-pillars, and bridge girders. The capital speculation required to develop and prepare a precast plant incorporates the concrete blending gear, structures, focusing on beds, relieving frameworks, and hard work hardware.

To get an arrival on this venture, the structures and focusing on offices must be in steady use. Efficiencies underway permit the precast pieces to be manufactured on a daily practice and regular schedule.

The cost efficiencies of this kind of creation permit designers and engineers to choose the segments for a wide number of employments and make certain of accessibility and serious expense. Hollowcore boards, single-T, and twofold T shafts are utilized as floor elements in building development. Altered T bars bolster twofold T and hollow core elements.

These elements are normally utilized in blend in office space, extensions, and parking structures.

Fixed Cross Section Elements: The structure engineer is required to decide the prestressing powers and ligament areas in fixed cross segment circumstances. Two basic fixed segment configuration conditions are post-tensioned shafts and chunks for building or parking structure development, and braces for connect development.

Different uses of fixed area elements incorporate structures, for example, water tanks and post-tensioned pieces on-ground.

Level plate and level piece floor frameworks are unmistakably appropriate for the utilization of post-tensioning ligaments. Another famous framework is single direction chunk and pillar floor frameworks that are thrown set up. The structure engineer indicates a ligament profile geometry and a normal successful post-tensioning power important to fulfill the plan prerequisites.

The strength engineer for the post-tensioning organization at that point takes this necessity and produces a nitty gritty structure with ligament sizes and dispersing alongside harbor and join areas.

Completely Engineered Elements: Completely engineered elements require point by point engineering ceaselessly during structure and development. Instances of completely engineered structures incorporate segmental extensions, claim to fame travel structures, tanks, towers, arenas, drifting offices, and bizarre structure development. Plan of these structures requires extensive engineering exertion and frequently remembers for site investigation.

The unpredictability of these structures requires the engineer have a basic comprehension of auxiliary conduct, loads, prestressing impacts, and material conduct. Coordinated effort of endeavors among engineers, precast plants, and general contractual workers is required.

Precast Nonprestressed Elements: The significant contrast in gathering is that pretensioned elements require noteworthy plant capitalization and focusing on beds. Precast pieces can be manufactured on the place of work or in an office without focusing on beds and other hardware related to plant activity. Tilt-up dividers are a case of on location precasting.

On the off chance that a modest quantity of prestressing is required for conveyance, erection or last loads, it is given as single-strand post-tensioned ligaments.

The compositional board finish can incorporate shading, surface, or reproduced elective materials, for example, a block or stone. Colors or colorants are utilized in these extraordinary concrete blends.