RCC Staircase: Details, Types, Pros and Cons

The Reinforced Cement Concrete (RCC) staircase has been built with concrete along with steel rods. The RCC staircase helps to connect different levels of the building structure. The reinforced converse helps to provide strength and stability to the entire staircase, which enhances the load-bearing capacity of the staircase.

Discuss the components used in the RCC staircase construction

Different components have been used in the construction of the RCC staircases, which are as follows:

Tread

The tread is the flat and horizontal portion of the staircase, on which people can walk. In the case of the residential buildings, the width of the tread should be between 220mm and 250mm. In the case of public building structures, the width of the tread should be between 250mm and 300mm.

Riser

The vertical portion of the staircase is known as the risers. In the case of the public buildings, the height of the risers should be between 120mm and 150mm. On the other hand, for residential buildings, the height of the riser should be between 150mm and 180mm. This component of the RCC staircase helps to ensure that the foot of an individual does not fall through the gaps while they are walking on the staircase, thus providing safety.

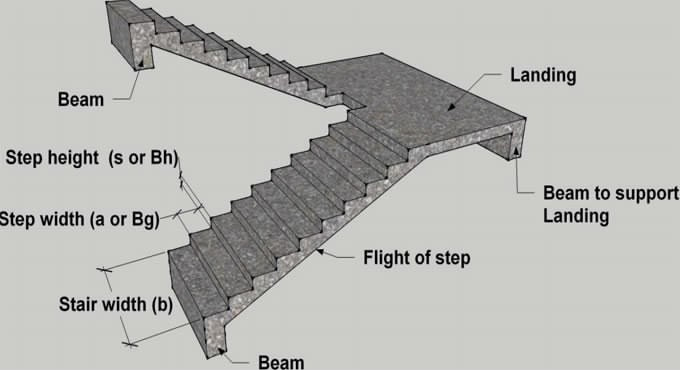

Landing

The landing portion of the staircase helps to provide a break from climbing up steps. The landing is required after almost 13 steps in a flight.

Supporting walls or beams

The supporting walls or beams help to support the entire staircase structure. The supporting beams or walls are present along with the width or length of the landings.

Importance of constructing RCC staircases

Higher strength

The RCC staircase has high compressive and tensile strength, which enables the staircase to resist the live loads and dead loads. This higher strnegthabilty of the RCC staircase makes it appropriate to be used in both low-rise and high-rise buildings along with larger occupancy levels.

Larger spans

There is a larger span of about 1m within the RCC staircase, which is appropriate for commercial building structures, for example, hospitals or shopping malls.

Long-term durability

The RRC staircase has less chance of undergoing rusting or rotting, which enhances its durability for a longer period of time, with little or no maintenance.

Resistance to fire

The RCC staircase has been made with non-combustible materials, which have better fire-resisting capacity as compared to the other types of materials.

Finishing options

The RCC staircase can be left exposed, which helps to achieve a raw and industrial aesthetic along with the treads, which are resistant to slip.

Consequences of constructing RCC staircases

Higher construction time and cost

The overall construction procedure of the RCC staircase is more time-consuming than steel or wooden staircases, which is also costly.

Higher labour cost

Because of the lengthy construction process, the labour cost for the RCC staircase construction is also higher.

Higher weight

The weight of the RCC staircase is higher compared to the steel or wooden staircases. This higher weight of the RCC staircase leads to an increase in the load of the foundation, thus enhancing the overall construction cost of the staircase.

Limited flexibility

The steel reinforcement bars, that has been used in the RCC staircases, are thick, making them tough to bend into the organic shapes.

Design procedures of RCC staircases

The RCC staircase has been constructed into several steps, which are as follows:

Concrete stair design

At first, each and every design aspect of the staircase, including the floor height, depth of the risers, stair width, thickness, angles and others, should be required by the engineers to design the perfect staircase.

Building foundations for stairs

In the next step, the foundation of the concrete stair has been constructed to transfer the load of the staircase to the ground. This foundation structure helps to support the staircase by restricting its movement.

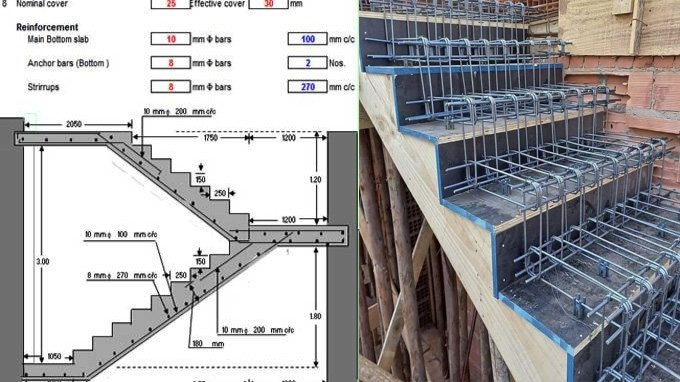

Building formwork

After constructing the foundation structure, proper formwork has been built to create the steps of the staircase. The formwork board should be at least 2” thick to support the concrete that has been poured into the formwork. In the formwork, wooden boards have been used, which have been fastened with screws.

Steel reinforcement

The concrete steps of the staircase have been reinforced with steel bars, which help to carry and transfer the loads of the staircase to the ground. The number of steel bars that have been reinforced into the staircase has been decided by the structural engineers on the basis of the loads coming on the staircases.

To learn more, watch the following video tutorial.

Video Source: Clueless Junkie

Concrete pouring

In the next step, concrete mix has been poured into the formwork, which helps to increase the strength and durability of the staircase. While pouring the concrete mix, a concrete vibrator was used to fill the gaps of the stairs, as well as to avoid the hypocomb formation.

Removal of the formwork

After concrete pouring, it should be left for at least 21 days to dry, and after that, the formwork should be removed. During the 21 days, the concrete should be cured properly with water to prevent cracks in the stairs.

Finishing the staircase construction

After removing the formwork, the trowel or float can be used to give the concrete finish in the stairs. In addition, cement tiles or granite can also be installed in the RCC staircase to achieve a better appearance.