Concrete Hardness Testing by Rebound Hammer

Tests that don't cause any damage to the construction material are also useful methods of evaluating the strength. When concrete, blocks, bricks, and the like have already lain out, it can be difficult to perform destructive tests on them. After establishing figurative support through its application, they provide an independent test sufficient to justify structural decisions. RCC structures can be repaired using this method when the concrete's hardness must be determined.

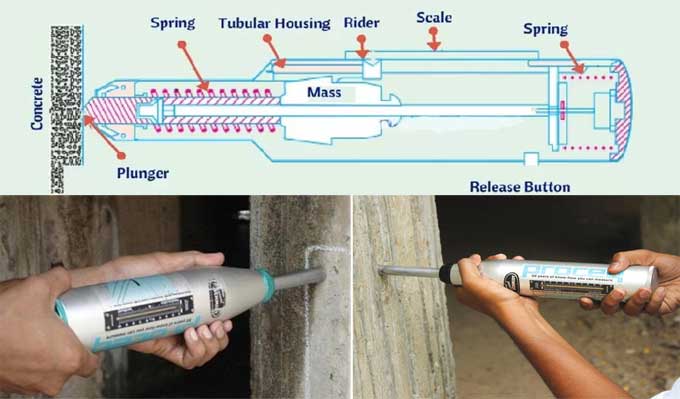

The concrete compression test is based on the hardness of the concrete at or near its exposed surface to measure the concrete's compressive strength. Schmidt developed the rebound hammer, also known as the Swiss Hammer when he was a Swiss engineer in 1954.

Test Procedure

A spring-controlled mass of constant energy strikes the concrete surface by pressing the plunger of the rebound hammer onto the concrete surface. A mass controlled by springs also returns at that moment. The hardness of the surface refers to the degree of rebound. Rebound Numbers or Indexes refer to this measured value.

Precaution

Clean, smooth, and dry surfaces are ideal. It recommends rubbing off any loose surfaces with a grinding wheel or stone before testing. At least 20mm should be spared from sharp edges and discontinuities. Incompletely compacted concrete, loss of grout, or spoiled or tooled surfaces should not be the test subject.

Rebound Hammer Test Graph

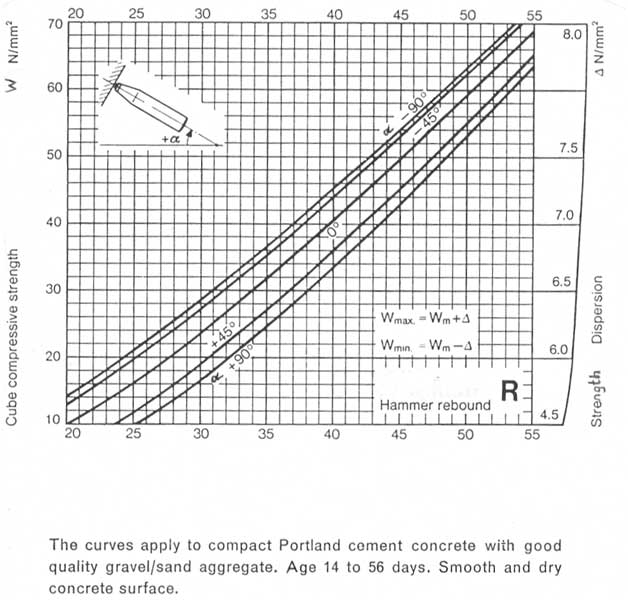

Concrete's strength and rebound number correlation according to the rebound hammer test graph. This angle is referred to as A. Perpendicularly smash concrete components or other materials with a rebound hammer.

Performing the test on hardened concrete requires calibrating the rebound hammer. Testing the concrete cube of size with a rebound hammer and then using the compression testing machine (CTM) is the most suitable method for checking the calibration of the rebound hammer. The rebound hammer strength checks out exactly with the CTM results to use it. The rebound hammer needs to be calibrated before testing if a large difference in results.

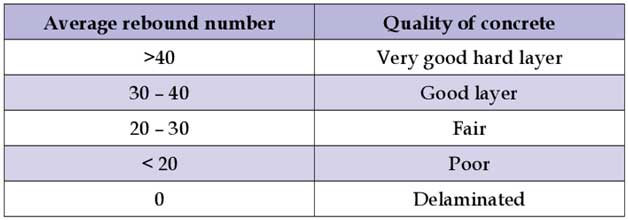

Concrete Quality Checking based on Rebound Number

It is extremely difficult to predict how the results of a rebound hammer test will turn out because many factors influence them. The strength of concrete can only be measured if all specimens and concrete are standardized for both the specimen under test and the calibration specimen. An engineer, then, must perform several tests before deciding whether to repair or strengthen an existing structure and then make a judgment based on the findings of the tests.

Types Rebound Hammer Test

A concrete test hammer comes in two different versions:

Type N

Testing a wide range of concrete elements and structures is possible with Type N test hammers, which have an impact energy of 2.207Nm. For concrete thicknesses exceeding 4in or 100mm, Type N hammers are used. In-place strengths are 1,450 to 10,152psi. Concrete cross-sections are thinner than 2 inches are not suitable for these types of analyses as they have limitations when applied to green concrete of early age with low strengths.

Type L

Compared to Type N models, L rebound hammers give lower impact energy of 0.735Nm. This model is more reliable for testing green concrete or areas that are less than four inches or one hundred millimeters thick.

In precast pipe construction and post-tensioning of early concrete, they are ideal devices. Concrete with thin cross-sections is also less likely to be damaged cosmetically and structurally with Type L hammers. With the Mushroom Plunger accessory, a Type L model can be used for accurate rebound testing on concrete that only has a compressive strength of 725psi or less.

To learn more, watch the following video tutorial.

Video Source: Civil Site visit