Everything You Need to Know About Spalling Concrete

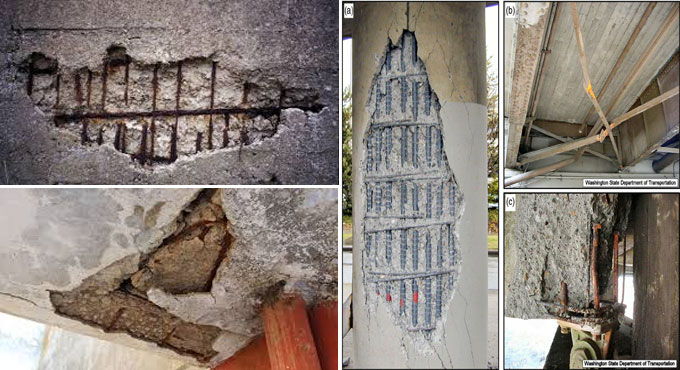

Spalling of concrete or concrete spalling is where barely any pieces of the concrete break itself liberated from the structure and uncover the fortification or the internal parts of the concrete to the air.

Spalling is brought about by certain chemical reactions inside the concrete which lead to the development of unfamiliar items which are of high volume. These new items because of absence of room inside the concrete, will build the inner weight. Thus, splits are shaped to deliver this weight outside.

These breaks thusly will clear path for the air to additionally respond with the inside environment of the concrete and possibly expanding the risk of disappointment. The splits will additionally engender and make the concrete tumble off. It tends to be perceived that this issue is for the most part brought about by the Prevention of new items.

Common reasons why concrete spall:

These issues causing new items are framed because of the accompanying conditions:

1. Corrosion

2. Alkali aggregate reaction

3. Chemical attack

4. Sulfate attack

5. Pollution

Spalling may likewise be brought about by presentation to high temperatures generally in the event of fire.

Impacts of Spalling of Concrete:

a. The concrete garbage may harm the individuals or harm the items underneath, hence expanding a mind-blowing danger.

b. The support in the concrete is presented to the environment in this manner expanding its weakness to erode. Corrosion will in the long run pave the way to the disappointment of steel and may significantly trigger the breakdown of the entire structure.

c. Due to spalling concrete, the territory of the concrete opposing the heap is diminished. This decreases the occasion, burden, and shear conveying limit of the structure.

d. The corrosion of the fortification will continue spreading if not treated appropriately. This will expand the support costs related with the fix.

e. The spalling of concrete will ruin the tasteful appearance of the structure, diminishing its worth.

Causes of Spalling Concrete and Prevention:

Lacking Cover: Lacking cover will build the weakness of the fortification to the environment. Indeed, even the smallest split on a superficial level will uncover the support. At the point when steel interacts with water and air, it erodes. The results of the corrosion have high volume than that of steel causing high inner weight and, in this way, causing spalling.

Prevention: Proper basic plan, legitimate management or careful treatment of the materials.

Freeze thaw Cycles: In chilly climate locales, the leaked water will go to ice which is higher in volume than that of water.

Prevention: This expanded volume can be overseen by making counterfeit air pockets inside the concrete with the assistance of air entraining operators.

Alkali Aggregate Reactions: At the point when the alkali in the concrete responds with the silica in the aggregates within the sight of water, it will shape the Alkali Silica Gel (ASG) which is higher in volume than the ordinary results of hydration.

Prevention: Alkali aggregate reaction won't happen if any of the three components ? water, alkali or silica are absent. Thusly, the reaction can be crippled by diminishing the alkali content in the concrete or utilizing silica free manufactured aggregates.

High Temperature: Dangerous spalling may happen during fire or when concrete is presented to high temperatures which causes high pore pressure created by the oversaturation. High quality concrete is more powerless against disappointment under high temperature than that of typical quality concrete because of the expanded fragility.

Prevention: Increasing the fire security of the structure will decrease the danger of hazardous spalling.

Inappropriate Compaction: Inappropriate compaction may leave the fortifications presented to the environment starting corrosion and in this way spalling.

Prevention: Proper management and utilizing vibrators to guarantee appropriate compaction will redress the issue.

Inappropriate Water Content: Low water substance will diminish the functionality and make it hard for compaction. This may prompt the development of unintended air pockets which may later clear a route for break Prevention.

High water-concrete proportion will decrease the quality of the concrete hence making it more defenseless against miniature breaks and in this manner spalling.

Prevention: Correct blend plan proportion, appropriate management must be followed to evade any accidents during the blending cycle.

Sulfate Attack: It is brought about by sulfate rich concrete or the sulfates present in the climate. The decay of the results of the hydration reaction prompts decrease in the quality of the concrete and in doing so causes spalling.

Prevention: Using sulfate opposing concrete and diminishing the porousness of the concrete.

Chloride Attack: This happens in the structures presented to the ocean water. Chloride attack will straightforwardly make corrosion the steel fortifications instigating the spalling concrete.

Prevention: Increasing the concrete cover, covering the fortifications with against rusting paints.

Bad Finishes: An unpleasant surface finished structure will in general gather more water on a superficial level than a smooth surface finished structure. The unpleasant finished structure will expand the drainage of water and may empower spalling.

Prevention: Provide smooth finishes.

Dirtied Environment: The pollution in the environment will likewise cause chemical attack on the concrete. The toxins with sulfide components will join with water and entrance into the structure and cause spalling.

Prevention: This can be stayed away from by applying water repellent paints on the surfaces.