Concrete Tensile Strength Test in Construction

The tensile strength of concrete measures its ability to resist the application of tension. In the split cylinder method of tensile testing of concrete, the strength of concrete determines. Units of force per cross-section are used to quantify the tensile strength of concrete. A concrete's compressive strength is good, but it has a weak tension strength. Concrete reinforcement was added to prevent cracks in this situation as a counterbalance.

Why concrete is weak in Tension?

As concrete isn't a solid material, it is not strong in both tensions and compressions like steel. A cement-water-aggregate mixture is used to make cement.

Interfacial Transits Zone (ITZ)

Among the structure's weak points is the Interface Transition Zone. Aggregates transfer load from one region to another when pressure or force is applied. Therefore, compression stresses do not require much strength in concrete. In the case of tensile stresses in the concrete, the aggregates are pulling apart from each other, so this interfacial transition zone must bear these stresses to maintain the strength of the whole system. Due to the weaker strength of the interface zone, failure can begin at lower stresses.

Tensile Strength of Concrete Test

The tensile strength of concrete is measured using the split cylinder method, which is ideal for constructing roads and runways. Generally, concrete's tensile strength varies from 10% to 13% of its compressive strength. Usually, concrete samples measure the compressive strength of concrete cubes, while cylindrical samples test tensile strength.

Specification of Test

Specimen & its Number

Concrete specimen is measuring 150mm in diameter and 300mm in length. Three samples are required for a fair comparison.

Load Range

Loading Machines can apply a constant load rate of 1.2 to 2.4 MPA per minute. These tests are usually conducted using a universal testing machine.

Test Age

It is recommended to perform the test at age 7 days and 28 days.

Apparatus Required

1. 1.2 to 2.4 MPA per minute testing machine.

2. 16mm x 600mm tamping rod.

3. Steel is used to make concrete moulds.

4. Trowel.

Procedure

1. Get a sample of high-quality concrete.

2. Make sure the cylindrical mold is free of dust and rust.

3. Concrete should be poured into the mold in three equal layers and properly compacted using a tamping rod.

4. The trowel should be used to smooth the top surface of concrete.

Curing

1. Wet gunny bags should be placed over mold with concrete samples, or mold should be kept undisturbed at 27 ? Celsius for 24 hours.

2. Take the sample out of the mold after 24 hours and remove the concrete samples from the mold. Immerse the concrete samples in the water for 7 or 28 days, based on the test.

3. Ensure the water sample is dry before taking the test by taking it after 24 hours.

Test

A. A dust-free loading strip and bearing surfaces.

B. Prior to testing, the specimen must be weighed in Newton.

C. Ensure that the upper platen and bottom platen are parallel, and then place the specimen between them.

D. When the specimen breaks, apply the load gradually until it breaks.

E. A similar procedure has been used for other samples.

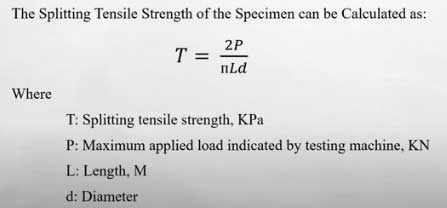

Formula

Report

Detailed information about the testing should be included in the report,

A. Test Age.

B. The date on which the specimen was cast.

C. Specimen weight.

D. A concrete's grade.

Conclusion

This study aims to develop a new approach to testing tensile strength characteristics by reducing traditional drawbacks such as eccentric loading, uneven stress concentration, and non-uniform strain loads in Traditional test methods. The tensile stress-strain curve of this material is much simpler than for Traditional methods since this material undergoes uniform tensile stress. As a result of identical internal forces of specific alignment within specific compression and tension elements, the elementary configuration of biaxial stress states can be modeled as strut tie models. A laboratory experiment conducts to investigate the reliability and splitting performance of the introduced model.

Based on the results, the proposed model determines higher tensile strength than the Brazilian test, with a greater error deviation and lower tensile strength than the flexural test. Despite no mechanical damage, fractures may occur when a gauge length broke.

To learn more, watch the following video tutorial.

Video Source: Anime_Edu - Civil Engineering Videos