Different Types Of Admixture for Concrete

Admixtures are mixed with the concrete for reducing water content, mitigating the setting property, making concrete light, and also modifying concrete properties. Admixtures are added right before or during the mixing of concrete. Excessive amount of water may cause extra bleeding and separation. That is why admixtures are added to the concrete to prevent all of this problem. Many types of admixtures provide the combination of plasticizer, superplasticizer and air entrainers.

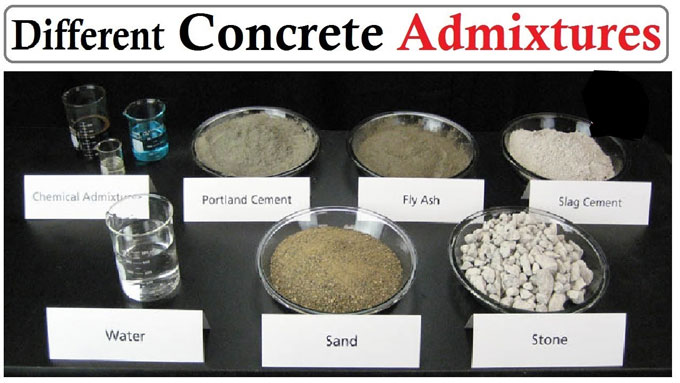

Basically, there are two type of admixtures available. One is natural admixtures and another is chemical admixtures. Natural admixtures are rice husk, flour, egg mix, ghee and the chemical admixtures is GGBS, fly ash, pozzolana.

In previous time, natural admixtures were used widely but this was very expensive and not much modification was not possible in that time. On the other hand, usage of chemical admixture provides variety in the construction industry.

Types of Chemical Admixtures

1. Plasticizers

2. Superplasticizers

3. Accelerators

4. Retarders

5. Air entrainers

Plasticizers

This are used for improving the plasticity of fresh concrete to reduce water content. Workability and water cement ratio do not affect because of using plasticizer. There are few types of plasticizer available like calcium, sodium, ammonium, lignosulphonates, polyglycol esters. These are added 0.1% to 0.4% ratio.

After adding this element is absorbed on the cement particles. This element also creates expulsive force named zeta potential. This expulsive force depends upon the used amount of plasticizer.

Advantages

1. Plasticizer also prevent the hydration of cement.

2. When polymer becomes entrapped in hydration products the plasticizer also decreases.

3. Plasticizer also increase the slump of concrete mixture.

4. Plasticizer is also able to reduce water content up to 10%.

5. It also increases the ability of pumping maintain strength and it does not affect the structure.

Superplasticizer

It complete different from plasticizer chemically. It also made of same elements but it is most commonly used in the production of high strength company. Before placing superplasticizer should be used otherwise it does affect the workability a lot. C3A has a huge effect on superplasticizer.

Advantages

1. If higher amount of superplasticizer helps to make high strength concrete.

2. It also helps to produce self-compacting and high-performance concrete.

3. It also has the capability for reducing water content up to 20% to 40%.

4. Higher molecular mass can be increased in the concrete because of superplasticizer.

5. It is able to produce more workable concrete and also maintain the same water cement ratio.

6. It doesn?t affect the workability.

7. It can lower the water cement ratio by reducing cement content and increase the strength of concrete.

Naphthalene sulphonates formaldehydes condensates is example of superplasticizer.

Air Entrainers

This type of admixture uses the air in the form of bubble and distribute throughout the cement paste. Air entrainers are used when resistance of concrete increases to protect the concrete against freezing. By adding this the concrete mis get more ability of work. This type of admixtures is also used to prevent bleeding and segregation. Amount of air entrainer is 1%.

Advantages

1. It also reduced the dead load of structures.

2. It also reduces aggregate content.

3. Air entrainers is also able to prevent the heat of hydration.

4. It is affordable to everyone.

5. It also reduces modulus of elasticity and unit weight of concrete.

6. It is also able to decreases the permeability in concrete.

7. It is very good resistant of chemical attack.

Accelerators

The type of admixture increases the setting property of concrete mix. It also increases the strength very much. This is very good as a rapid setting while making marine structures. It is also used in cold areas. Calcium chloride, sodium chloride, sodium sulphite, sodium hydroxide, sodium carbonate, potassium hydroxide and potassium sulphate are the examples of accelerators.

Though calcium chloride is not used in reinforced structure and water retaining structure because it increases the erosion in steel. This type of admixtures works very good in low temperature.

Retarders

This type of admixture can low the setting property of concrete. It is also able to slow down the chemical reaction between cement and water. It also gains strength. When the mixture of cement transport in long distant place and in hot weather to prevent workability.

There few examples of Retarder are mentioned below. These are sugar, lignin, hydroxylated carboxylic acids, phosphates, cellulose. The disadvantages of it are that it also increases the plastic shrinkage and help to increase cracking.