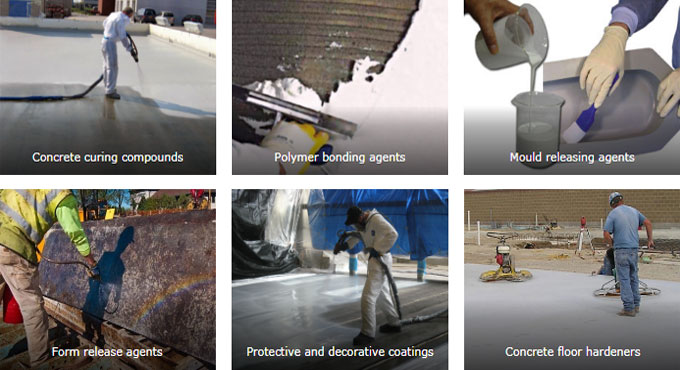

Various types of construction chemicals

Construction chemical is given paramount importance in all type of construction projects. This type of chemicals is very frequently used to get desire qualities like workability, flexibility.

There is different type of construction chemical. Global chemical market of construction is increasing rapidly. Also, there is huge demand oof buildings, roads, tunnels that increase the market on daily basis.

Types of construction chemicals:

Concrete Curing Compounds

This type of concrete chemical is combination of waxes, natural and synthetic resins in certain atmosphere. This combination creates a moisture after applying on a concrete surface. Curing compound is not for those type of surface which has extra concrete, paint, tile.

Polymer Bonding Agents

This type of concrete chemical is combination of both polymer and chemical admixture. This type of concrete chemical is used in concrete and cement-based products in interior or exterior application. It is also used as a polymer modifier in mortars and concretes. It also increases tensile and strength of bond. this type of concrete chemicals is also very good resistant against chlorides de-icing salts.

Mould Releasing Agents

This type of concrete chemicals is very useful when the materials already shaped and constructed in moulds. If the releasing agent is not used then perhaps the mould may be damaged or broken. This type of concrete chemical has different types of texture. The most common type of texture is oil based. This placement is like placement of butter in the bottom of any dish to remove the cake.

Form Release Agents

This type of concrete chemicals used in the inner surface of any type of form. It also smooths the concrete surface. This type of concrete chemicals also increases the life circle of any type of the forms. Elements of this type of concrete is

a. Oil based

b. Resin based

c. Water based

d. Organic chemical based.

Protective & Decorative Coating

This type of concrete chemicals is a coating of layer. It is used on the surfaces to prevent any type of erosion. This type of coating can be metallic or nonmetallic. It can be used in different way. It has different purposes other than preventing erosion.

The ingredients which are used in nonmetallic polymers, epoxies, polyurethanes. The used ingredients in metalic coating are zinc, aluminium, chromium. last but not the least there are few special materials also used in finishing coat of plastering to fulfill the other requirement like decorative appearance, high flexibility fire proof heat and sound insulation high strength and many more.

Rebar Coating

This type of coating is for reinforcing steel bars. It is used when the steel bars have to be exposed to weather for certain amount of time.

This type of coating prevents the rust on the steel bar. The rust on the steel bars otherwise removed by grit blasting or sand. A very common type Rebar coating is fusion bonded epoxy coating. Also, steel bars can be galvanized.

Epoxy Grouts

This type of concrete chemicals is perfect for rough environmental condition like extreme temperature oil or acids. This type of grouts is more flexible impact and has capability of resistance stain. This type of grout is very costly. This type of grout has very good vibration of damping qualities so it is very good for machine foundation or industrial equipment.

Epoxy Coating

This type of coating is mainly oil based or water-based solution. It is also solvent free. It may have single or two components. Single component epoxy coating is basically oil based. the two-component epoxy coating is a mixture of situ. The two-component epoxy coating are very good for factory, industrial or commercial building. This is generally directed by manufacturer.

This type of coating has qualities like chemical and thermal resistance, hardness, flexibility and waterproofing. This type of coating is also used in floors to decorate the floors in many ways.

Construction Chemical for high performance Concrete

Nowadays construction chemical is using in high performance concrete to achieve the mechanical strength. This type of concrete has special compressive strength of 8000 psi or more than that. Extra care is required for this type of concrete so that professionals can understand about the required structural design.

Waterproof Chemicals

This type of concrete chemical is very useful for certain situation. This type of chemical gives an extra effort to those type of structure which is specially made for dealing liquid most of the time. There are many varieties of this type of chemicals. The types are

a. Crystalline waterproofing chemicals.

b. Liquid acrylic elastomeric waterproofing compound.

c. Polymer waterproofing compounds.

d. Cementitious waterproofing compounds.

These types of compounds create membrane on the surface of concrete for protecting against water.

Swelling Water Stops

This type of concrete chemicals generally used in construction joint. It is very easy to install. This type of concrete chemical is also very cheap than others. These types of chemicals seal the joints by swelling. Example of this type of chemicals are polyurethane foams and grouts. Swelling PU resins which can be turned into foamy in contact with water. It is used to seal leakage cracks.

Image Courtesy: constrofacilitator.com