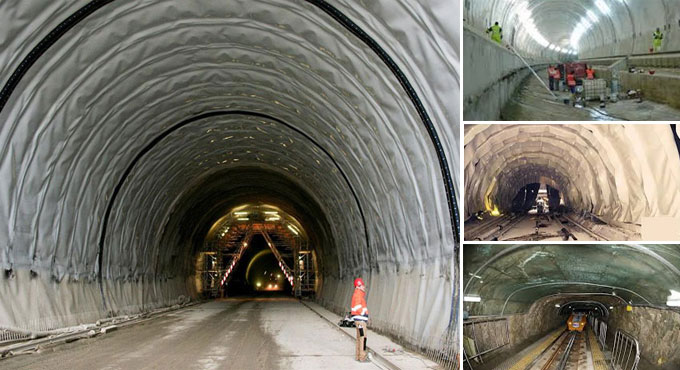

Various Types of Waterproofing System of Tunnel

Waterproofing of tunnels is the most important matter of the tunnel industry. But due to the surrounding conditions it is very tough that tunnel is protected from groundwater percolation. Waterproofing system of tunnel requires different types of category like flexibility, exposure and stress condition. If waterproofing of tunnel not works well then it can?t protect tunnel from moisturizing. In result tunnel would get damaged and water, soil or chemicals enter inside of the tunnel.

Various problems of water infiltration

Infiltration of water inside of tunnel is the worst thing would happen to tunnel. ITA stands for International Tunneling Association. ITA provided a report about how infiltration of water can damage the whole system of tunnel.

This report is based on case histories taken from various countries. They also showed in this report about seventeen types of defects and different remedies. In urban areas there is one more problem. That is infiltration of chemical based water inside tunnel.

Criteria for good quality of waterproofing system

There are different criteria is necessary to meet the good quality of waterproofing system in tunnel. The criteria are mentioned below.

1. Different types of structure.

2. Various types of construction like cut and covered and bored.

3. Lowest mound of structure.

4. Maximum state of groundwater after construction.

5. Different surrounding environmental situations like Ph, hydrocarbon, chemicals at site.

6. Easy installation process.

7. Track record of the system.

8. Cost of construction.

9. Maintenance of waterproofing system.

Waterproofing system of tunnels has to be planned so that any type of solution is possible if there is any problem. Permanent eater table, water tightness, workmanship, safety standards and sensitive area are most important criteria for choosing waterproofing system of tunnel.

Various types of waterproofing system of tunnel

There are various types of waterproofing system are available here.

1. Liquid waterproofing system: Liquid waterproofing system has the longest track record preventing against infiltration. It compromises rubber, tar, polymer etc. This type of system is applied to increase the temperature of material at 100 degrees. It requires electric or propane fired kettles. This system also requires manpower and the material is placed by mops or hand.

2. Panel waterproofing system: This type of system uses swelling Bentonite in a fabric roll or cardboard. the Bentonite is good to use as waterproofing barrier. This inflation happens within 4 hours of contact with water. The panel must be placed in dry area and also attached to the concrete. The attachment area should be coated with mastic to prevent infiltration in the panel.

3. Membrane waterproofing system: Membrane waterproofing system is applied vertically or horizontally. This system is made of membrane. It also has a fabric filter layer. The membrane must have uniform surface to complete bonding.

4. Epoxy liner waterproofing system: This type of system used on bridge decks at first. This system has two system and these two are produced by two formula. One is for vertical surface and other one is for horizontal surface. This is not interchangeable to develop necessary thickness. This type of system is installed by spraying epoxy.

5. Hybrid waterproofing system: This type of system is combined of technology of active polymer barrier and passive bonded product technology. Different material layers are combined in this system to prevent any kind of failure.

6. Cementitious waterproofing system: This type of system is combined of co-polymers and Portland cement. This two-material use copolymers to prevent infiltration of water molecule through coating. This type of coating is generally used where exterior concrete surface is not possible.

7. Spray-on waterproofing membrane system: This type of system contains single shell lining. This type of process can bond to primary and secondary lining. This type of system is very good for maintenance and repairment. This type of system can prevent movement of water.

The water added in their must show static pressure of minimum 2 bar. This nozzle should be handled by one man. action capacity of this system is more than 50 m2/h.

Wrap up

Waterproofing of tunnel is very tough because of high risk. If waterproofing of tunnel is failed then it is very dangerous. The designers and project managers should understand the functioning detail of waterproofing system.